¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

También conocido como:

Service

In Stock

Service

New

API

Land Freight

Soluciones

Customized Equipment Manufacturing: Designing and manufacturing specialized tools for unique well service needs.

Fishing and Retrieval: Providing expert fishing services for the retrieval of lost or stuck equipment.

Comprehensive Pressure Management: Deploying advanced pressure control equipment for a wide range of well conditions.

Geothermal Services: Delivering specialized interventions for the maintenance and performance enhancement of geothermal wells.

Advanced Downhole Operations: Offering sophisticated downhole services, including slickline and wireline interventions.

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Para información sobre productos o servicios, personalización u otras preguntas

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

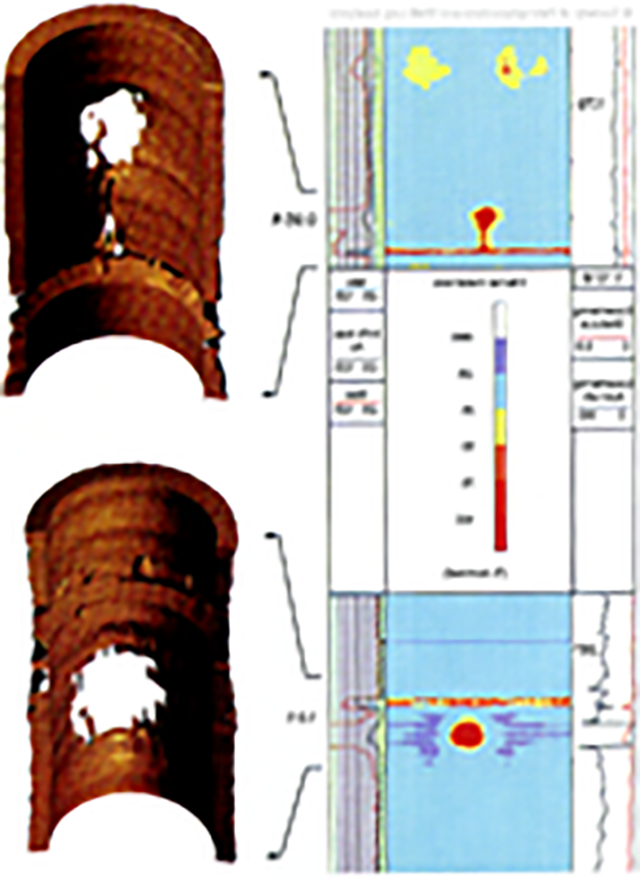

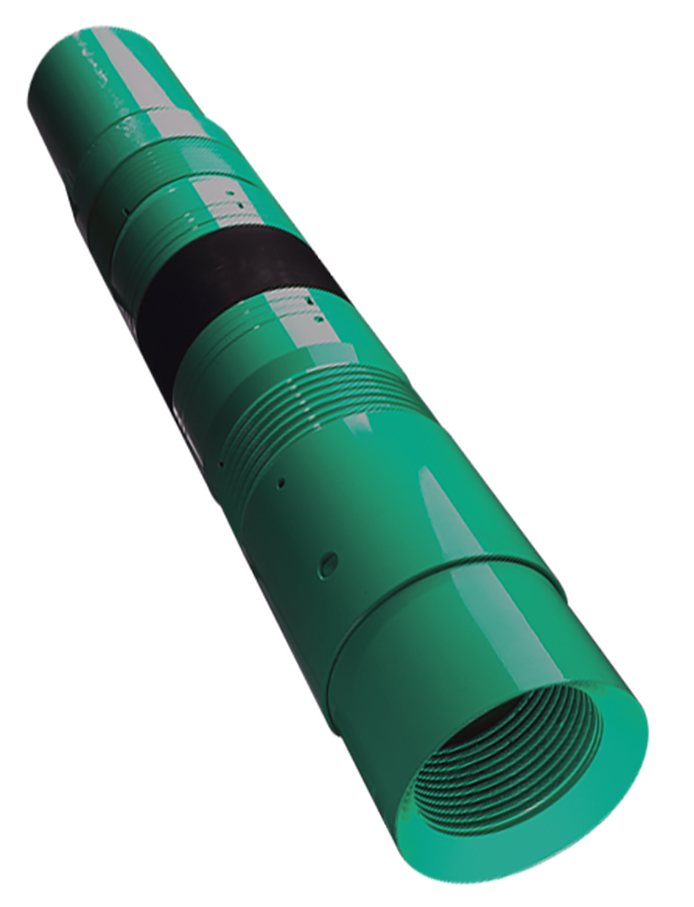

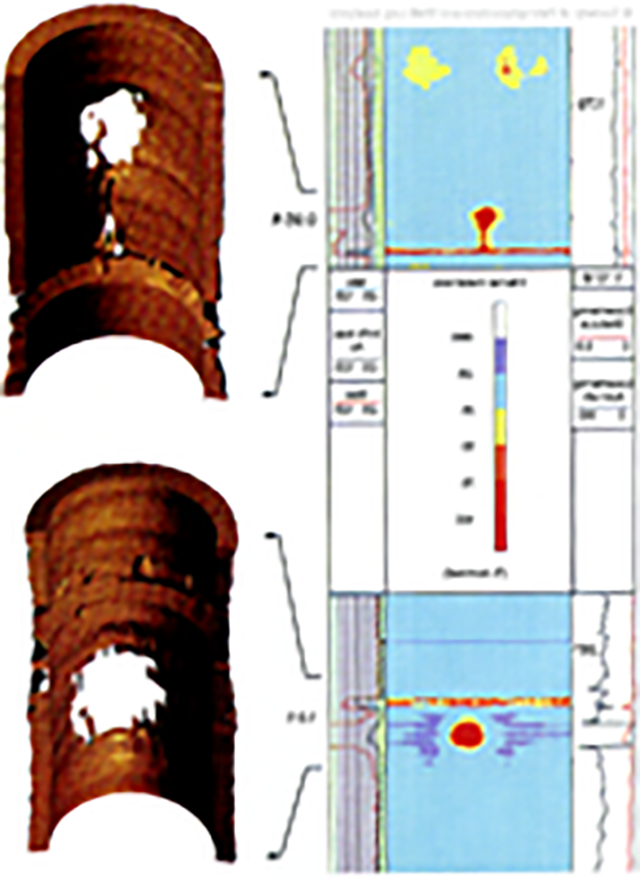

Elevating Well Integrity Analysis with InWaTec Combined's CBL-VDL Services Ensuring a solid cement bond between casing and the wellbore is not just a procedural step; it's a critical factor in well integrity that demands the most meticulous evaluation techniques. InWaTec Combined’s Cement Bond Logging (CBL) and Variable Density Logging (VDL) Services offer a refined approach to acoustic well logging, a method that has been a research focal point due to its importance in ascertaining well safety and functionality. Cement bonding evaluation can be segmented into two categories based on tool source frequency: the sonic method (around 20 kHz) and the ultrasonic method (several hundred thousand Hz). The sonic method, a technique that has stood the test of time since its introduction in 1963, provides a qualitative or semi-quantitative analysis of the cement bond. It involves the excitation of a sonic wave and measurement of its attenuation along the borehole axis, with the degree of attenuation reflecting the quality of shear coupling behind the casing. Simply put, the greater the attenuation, the better the bond. CBL specifically focuses on the attenuation factor derived from the first arrival amplitude, offering a snapshot of the bond's integrity. In contrast, VDL takes into account the full waveform amplitude, providing a more detailed and denser representation of the bond quality. These dual measurements, with industry-standard receiver spacings of 3-ft for the casing wave and 5-ft for the full wave, allow for a comprehensive analysis of the cement bond. InWaTec Combined's CBL-VDL Services employ these methodologies with precision-engineered tools that capture high-resolution data, enabling our experts to discern even subtle variations in bonding conditions. This data is not merely numbers on a log; it's a story of the well's integrity, revealing areas of potential concern that can be proactively addressed to prevent non-productive time and ensure operational safety. By leveraging the combined strengths of CBL and VDL, InWaTec Combined provides clients with a robust assessment of their cementation quality. The detailed logs produced not only satisfy regulatory requirements but empower operators with actionable insights to optimize their well construction and maintenance strategies. Choose InWaTec Combined's CBL-VDL Services for your cement bond evaluation needs and gain peace of mind with our thorough, reliable, and cutting-edge acoustic logging solutions. Our commitment to excellence in well logging means that when it comes to well integrity, you're not just meeting industry standards—you're setting them.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

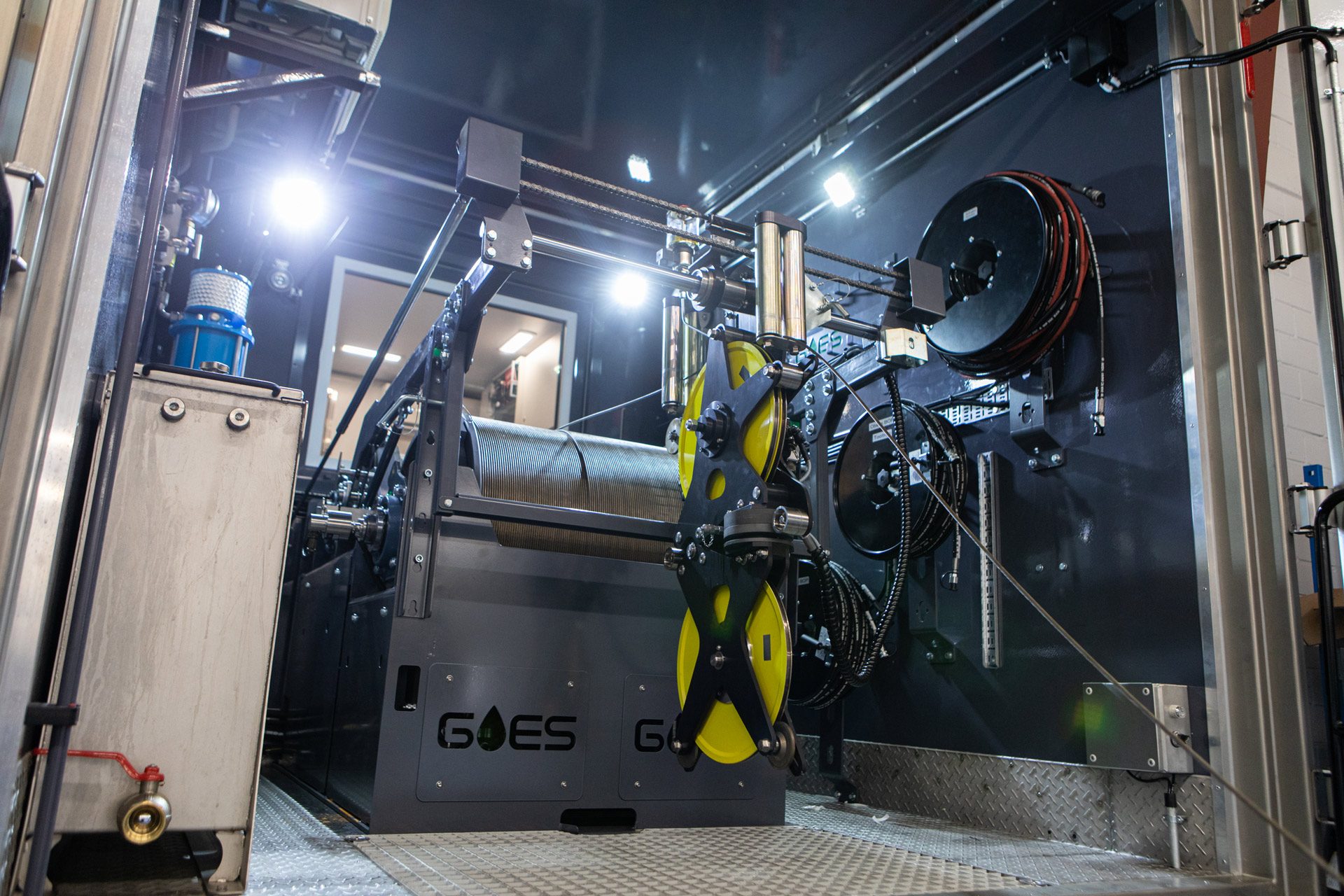

InWaTec Combined's Onshore Slickline Services: Ensuring Efficiency and Safety in Populated Areas In the bustling landscape of onshore oil and gas production, where operations often lie in close proximity to populated areas, the need for precision, safety, and minimal environmental impact is paramount. InWaTec Combined's Onshore Slickline Unit services are tailored to meet these critical requirements with unparalleled expertise. Precision Downhole Operations Our slickline operators are masters of their craft, adept at raising and lowering an array of downhole tools with the utmost precision. Using a robust single strand wire cable, they execute well testing and maintenance tasks with finesse. Tools such as bailers, pulling tools, stems, and running tools are maneuvered with exactitude to ensure the optimal performance of your wells. Innovative Tool Retrieval and Installation The versatility of our slickline services extends to the retrieval and installation of essential well components. Whether it's valves, plugs, or pressure regulators, our skilled operators can install or retrieve these with minimal intrusion. This is especially critical in onshore sites where operational efficiency and speed are key to minimizing the impact on nearby communities. The Slickline Advantage Slickline is not just a tool but a solution. It represents a niche within the industry that InWaTec Combined has perfected. The use of a slickline truck or undertaking a slickline job embodies our commitment to providing specialized services that cater to the unique demands of onshore well sites. Tailored for Onshore Challenges Recognizing the unique challenges presented by onshore well sites, especially in populated areas, our slickline units are designed for minimal footprint and rapid deployment. This ensures that our operations are not only effective but also considerate of the surrounding environment and community. A Partner in Responsible Well Servicing InWaTec Combined is more than a service provider; we are your partner in ensuring that onshore well operations are conducted responsibly, safely, and efficiently. Our Onshore Slickline Unit services are a testament to our dedication to operational excellence and environmental stewardship. In summary, as the oil and gas industry evolves, so do our services. InWaTec Combined is at the vanguard, driving onshore well servicing forward with our advanced slickline solutions, ensuring that your operations are sustainable, safe, and successful.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

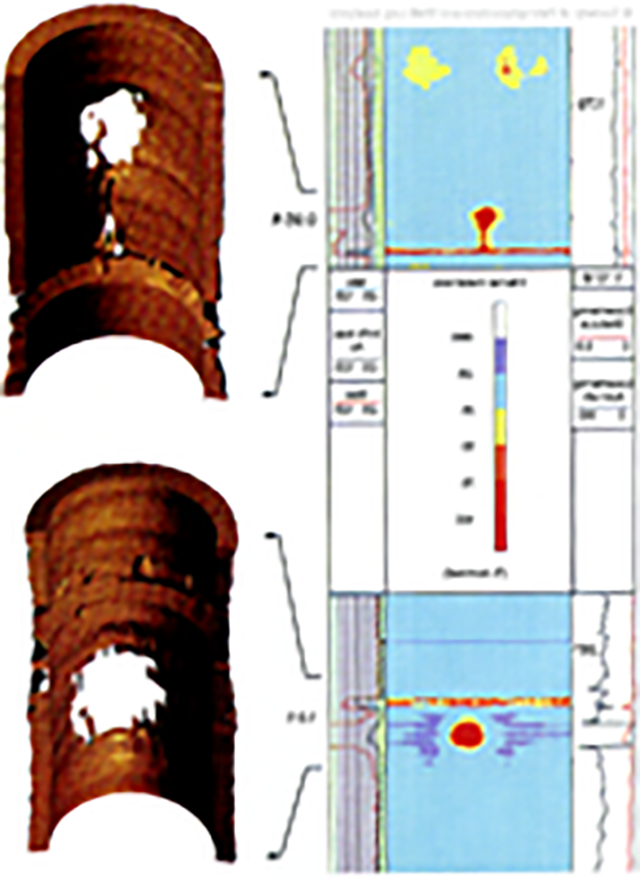

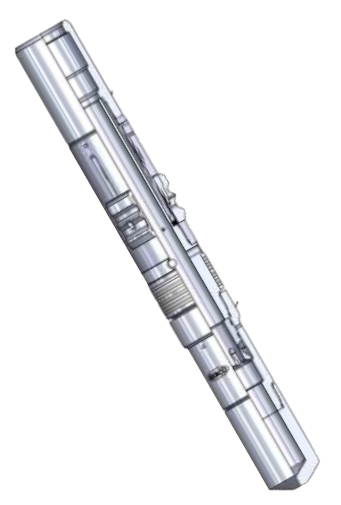

Unveiling Subsurface Precision: InWaTec Combined's PMIT Services for Optimal Wellbore Assessment In the ever-evolving landscape of the oil and gas industry, the quest for precision in subsurface analysis is relentless. InWaTec Combined's Platform Multifinger Imaging Tool (PMIT) Services stand at the forefront of this quest, offering unparalleled accuracy in the radial measurement of tubing and casing strings' internal diameters. The PMIT is an innovation par excellence, a multifinger caliper tool that delves into the heart of the wellbore to capture highly precise data. This tool is not just a measuring device; it is the embodiment of accuracy and technological sophistication. With its multiple sensor fingers, the PMIT glides along the tubing or casing surface, meticulously logging variations in the internal diameter that could indicate potential issues such as corrosion, wear, or deformation. Our PMIT services are crucial for ensuring the integrity and performance of downhole tubulars. With its ability to provide a 360-degree internal view, the PMIT helps operators make informed decisions about maintenance, workover needs, and overall well management. The accuracy of the PMIT’s measurements allows for the early detection of anomalies that, if left unchecked, could lead to operational failures or safety hazards. At InWaTec Combined, we believe that a thorough understanding of the wellbore condition is essential for the longevity and productivity of wells. Our PMIT Services deliver this understanding through detailed assessments that support proactive intervention strategies. The data gathered by the PMIT facilitates accurate planning for remedial operations, ensuring that any service performed is targeted and effective. In an industry where the margin for error is increasingly narrow, the PMIT offers a significant advantage. Operators can trust the data from our PMIT Services to reflect the true conditions within their wells, providing a solid foundation for all subsequent operational decisions. Choose InWaTec Combined's PMIT Services for your wellbore assessment needs, and experience the confidence that comes from precision technology and detailed, actionable data. Our commitment is to provide you with the insights necessary to maintain the highest standards of well integrity and performance. With InWaTec Combined, you are not just measuring the depths—you are mastering them.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

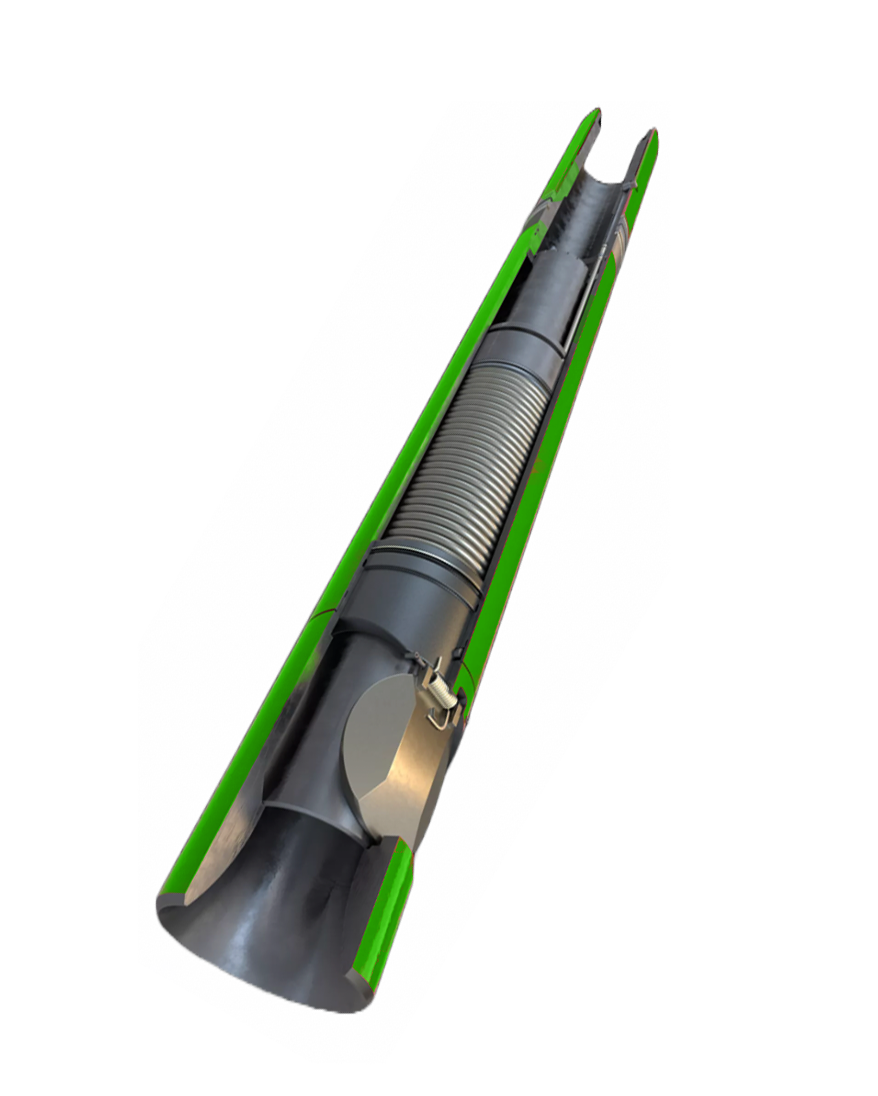

Enhancing Snubbing Operations: InWaTec Combined’s High-Pressure Mini-Coil Services At InWaTec Combined, we understand the critical nature of snubbing operations in well intervention and maintenance. Our Mini-Coil Tubing services are specifically designed to enhance these operations, providing a solution that balances the delicate requirements of fluid placement and well lifting with the necessity for high-pressure performance. Optimal Fluid Placement: The Mini-Coil Tubing is adept at delivering small quantities of fluids precisely where they are needed. This precise placement is particularly beneficial during snubbing operations, where control and accuracy are paramount to successful well control and intervention. Efficient Well Lifting: When it comes to lifting wells into production, especially during snubbing operations, our Mini-Coil Tubing shines with its ability to handle high pumping pressures. This capability ensures that wells are brought into production efficiently and reliably. High-Pressure Operations: While Mini-Coil Tubing may face limitations in flow rate and mechanical snubbing force due to its smaller size, it compensates with an exceptional capacity for withstanding higher pumping pressures. This makes it particularly useful in situations where pressure integrity is crucial. The nature of snubbing operations often involves dealing with wells under pressure. The high-pressure resistance of our Mini-Coil Tubing means it can be deployed in environments that are too challenging for larger, conventional coiled tubing. This feature opens up new possibilities for conducting critical well interventions safely and effectively. InWaTec Combined's Mini-Coil Services are not just about providing equipment; they're about delivering a comprehensive solution. We understand that each well and operation has its unique set of challenges. Our Mini-Coil Tubing services are complemented by a team of experienced professionals who ensure that every operation is executed with precision, efficiency, and adherence to the highest safety standards. Customized Solutions: Recognizing the unique demands of each operation, InWaTec Combined offers customized Mini-Coil solutions. We work closely with clients to understand their specific needs and challenges, ensuring our Mini-Coil Tubing services are tailored to meet the particular requirements of their snubbing operations. Choose InWaTec Combined for your snubbing operation needs, and benefit from the advanced performance of our Mini-Coil Tubing services. Our commitment to innovation, safety, and operational excellence ensures your operations are not just maintained but enhanced. Let us help you achieve your well intervention goals with our high-pressure, precision-driven Mini-Coil services.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Seamless Zone Isolation: InWaTec Combined’s E-line Bridge Plug Setting Services In the complex operations of oil and gas extraction, the ability to isolate zones within the wellbore is critical for effective production management and intervention. InWaTec Combined offers specialized E-line Bridge Plug Setting Services, utilizing state-of-the-art tools to achieve precise zonal isolation with both permanent and retrievable bridge plug options. Bridge plugs are essential elements in completion hardware, designed to provide robust seals both above and below the production tubing within the casing, liner, or wellbore wall. Their primary function is to isolate certain sections of the well, which is especially beneficial in wells with multiple producing zones or when specific zones need to be temporarily sealed off during interventions. Permanent Bridge Plugs: These are typically favored for their cost-effectiveness and superior sealing and gripping capabilities. Once set, they provide a dependable barrier, with metal slips or "slips" that anchor into the casing's inner diameter using sharpened, carburized teeth. The seal is completed with large cylindrical rubber elements, and in high-pressure environments, metal rings enhance the seal by preventing rubber extrusion. Retrievable Bridge Plugs: These plugs are the go-to solution when flexibility is required, such as during secondary recovery operations, well re-completions, or when there's a need to change out production tubing. Though they may have lower sealing and gripping capabilities compared to permanent options, their design allows for removal and reuse, providing significant operational versatility. Our E-line Bridge Plug Setting Services deploy these tools with precision. The plug is conveyed into the well via wireline—a method that provides real-time depth control and selectivity. Once at the target depth, an axial load is applied to the bridge plug to initiate the expansion of the slips and rubber elements, creating a secure seal against the casing. The setting mechanism can be activated hydraulically, mechanically, or with a controlled chemical charge, depending on the well conditions and client requirements. InWaTec Combined’s expertise ensures that the most appropriate setting method is chosen for each operation, considering the well's pressure environment, the desired duration of the plug setting, and the future plans for the well. By opting for InWaTec Combined’s E-line Bridge Plug Setting Services, operators benefit from a service that combines reliability with adaptability. Our commitment to leveraging advanced technologies with expert execution means that your well operations can proceed with confidence, knowing that each zone is isolated with the utmost precision. InWaTec Combined is dedicated to providing solutions that enhance operational efficiency and well integrity. Whether you require a permanent solution for long-term isolation or the flexibility of a retrievable plug for short-term interventions, our E-line Bridge Plug Setting Services are designed to meet your needs with precision, reliability, and cost-effectiveness.

Service

In Stock

Service

New

API

Land Freight

Offshore Electric Line Services

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Navigating the Depths: InWaTec Combined's Advanced Offshore E-Line Services In the challenging and complex world of offshore operations, precise and dependable wellbore data transmission is not just beneficial—it's crucial. At InWaTec Combined, our Offshore Electric Line (E-Line) services are the cornerstone of our well diagnostics and intervention solutions, designed to conquer the unique demands of the offshore environment. An E-Line, in its simplest form, is a robust electric cable. Yet, when deployed by InWaTec Combined, it becomes an integral part of offshore operations, a sophisticated tool that delves into the wellbore's mysterious realms. Our E-Line services excel in transmitting real-time data about the wellbore's conditions back to our offshore experts, ensuring that critical decisions are made with the utmost information at hand. Our E-Line's forte lies in its versatility and utility in conducting a plethora of logging activities essential for evaluating the well's integrity, formation properties, and hydrocarbon potential. These activities enable a comprehensive understanding of the well, providing insights necessary for optimizing production and ensuring the safety of offshore operations. The offshore environment poses unique challenges with its unpredictable nature and the sheer scale of operations. InWaTec Combined's E-Line services are designed to be resilient and adaptable, capable of withstanding the high pressures and corrosive elements found in the deep sea. Our commitment to innovation means that our E-Line technology is continuously evolving, pushing the boundaries of what is possible in offshore data gathering. By choosing InWaTec Combined's Offshore E-Line services, our clients receive more than just data—they gain a strategic advantage. With our advanced technology and expert analysis, we provide the insights necessary to maximize well performance, extend the life of offshore assets, and enhance the overall safety and efficiency of offshore operations. In an industry where the margin for error is slim and the consequences significant, InWaTec Combined stands as a beacon of reliability and excellence. Our Offshore E-Line services are not just a component of your operations—they are a pivotal part of your success story, deep beneath the waves.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Ensuring Production Integrity with InWaTec Combined's E-Line Tubing Inspection Services In the lifecycle of oil and gas wells, tubing integrity is fundamental to ensuring consistent production and operational safety. At InWaTec Combined, we offer specialized E-Line Tubing Inspection Services to preemptively identify and mitigate risks associated with tubing failure, utilizing state-of-the-art diagnostic techniques to safeguard your assets. Tubing failures, which can stem from deformation, physical wear, or corrosion, pose a significant threat to well integrity and production. Our advanced inspection services are designed to detect these issues early, enabling timely interventions that maintain continuous well performance. Our comprehensive suite of E-Line Tubing Inspection Services includes: Cased-Hole Calipers: These tools provide precise measurements of the internal diameter of tubing, detecting anomalies and changes that could indicate deformation or wear. Flux-Leakage Tools: Specialized for identifying defects in ferrous tubulars, these tools locate areas of metal loss or corrosion by detecting disruptions in magnetic flux. Electromagnetic Phase-Shift Tools: By measuring the changes in electromagnetic fields, these tools can effectively pinpoint areas of wall thickness changes due to corrosion or wear. Ultrasonic Tools: Employing high-frequency sound waves, these tools are adept at measuring tubing wall thickness, identifying areas at risk of thinning, which could lead to potential collapse. In addition to these, our E-Line Tubing Inspection Services also employ ultrasonic radial-cement-evaluation and modified openhole-imaging devices, which are particularly effective in assessing the condition of the tubing for signs of internal or external metal loss—a crucial step in preventing unexpected well shut-ins. At InWaTec Combined, we understand that the stakes are high when it comes to maintaining well integrity. Our E-Line Tubing Inspection Services are not just about identifying problems; they're about delivering peace of mind. By utilizing our advanced diagnostic tools, operators can rest assured that the integrity of their production tubing is being monitored with the utmost precision, allowing them to focus on maximizing output and efficiency. Choosing InWaTec Combined means partnering with a company that places a premium on innovation, safety, and reliability. Our commitment to excellence ensures that your operations benefit from the latest in inspection technology, delivered by a team of seasoned professionals. Trust us to provide the insights you need to keep your wells flowing safely and smoothly, today and into the future.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Enhancing Well Efficiency: InWaTec Combined’s Precision E-line Packer Setting Services The backbone of any well’s structural integrity and operational efficiency lies in the strategic placement and setting of production packers. InWaTec Combined’s E-line Packer Setting Services provide meticulous installation of these critical components, ensuring an optimal seal and isolation within your wellbore. A production packer is not just a piece of hardware; it’s a guardian that ensures the separation of production zones, safeguards the casing from pressure, and enhances the overall management of the well. Our E-line Packer Setting Services cater to both production and service packer requirements, providing versatile solutions tailored to the unique challenges of your well operations. Production Packers: These remain in place during well production, set above the top perforations or sand screens. They are pivotal in multi-zone reservoirs, where they isolate perforations for each zone, allowing for selective production through the use of sliding sleeves. Service Packers: Employed temporarily during well servicing tasks like cement squeezing, acidizing, fracturing, and well testing, service packers are essential for the precise and safe execution of these operations. Packers are designed with a keen eye on reliability—metal slips and rubber elements, or metal rings in high-pressure scenarios, ensure a firm grip and seal against the casing ID. Our E-line Packer Setting Services employ the latest in axial load technology, whether hydraulic, mechanical, or chemical, to expand and secure these packers at the optimal depth. For permanent well configurations, our permanent packers offer a cost-effective and robust solution, boasting superior sealing and gripping capabilities. When retrievability is key, our retrievable packers provide flexibility for secondary recoveries, re-completions, or production tubing changes, with designs that ensure ease of removal and the possibility of reuse after servicing. InWaTec Combined’s commitment to excellence in E-line Packer Setting Services is unwavering. We provide not only the tools but also the strategic foresight and technical support to ensure that your packer installation enhances well performance, maintains integrity, and supports your production goals. Partner with InWaTec Combined for your packer setting needs and experience the assurance that comes from precision, durability, and adaptability. Our services are designed to secure your well’s future, one packer at a time.

Service

In Stock

Service

New

API

Land Freight

General Mechanical Slickline Service

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

InWaTec Combined: Precision at Depth with General Mechanical Slickline Services In the demanding arena of oil and gas well maintenance, precision is not just a virtue—it's a necessity. At InWaTec Combined, we provide General Mechanical Slickline services that bring precision to the heart of your well operations. Our slickline services deliver targeted maintenance solutions, assuring that performance, integrity, and productivity remain at the forefront of your downhole activities. The Role of Slickline in Downhole Maintenance Slickline is the unsung hero of well servicing, a slender thread of robustness, lowering essential tools into the depths of oil and gas wells to execute critical maintenance tasks. It is the conduit for precision, the means by which tools are delivered to the precise downhole location where they are needed. Why Choose InWaTec Combined's Slickline Services? Expertise at Every Turn: Our slickline operators are seasoned experts, with the skill to navigate complex downhole environments, ensuring that every tool is deployed with accuracy. Versatile Tool Deployment: From routine maintenance to emergency interventions, our slickline services cater to a diverse range of downhole needs, delivering the right tool to the right place at the right time. Streamlined Operations: Efficiency is key in downhole operations, and our slickline services are designed to minimize downtime, streamline processes, and maintain the peak performance of your wells. Safety and Precision Combined: At InWaTec Combined, we balance the need for operational precision with an uncompromising commitment to safety, ensuring that every slickline operation upholds the highest standards. Tailored Solutions for Downhole Challenges Every well presents its own set of challenges, and InWaTec Combined's General Mechanical Slickline services are crafted to meet them head-on. We provide tailored solutions, customizing our approach to fit the unique needs of your well, ensuring that maintenance tasks are carried out with precision and care. Advanced Technology for Optimal Results We leverage the latest in slickline technology, utilizing advanced materials and innovative techniques to enhance the reliability and effectiveness of our services. Our commitment to technological advancement means that we're always at the cutting edge, providing services that are not just current but future-ready. Your Partner in Well Maintenance Choosing InWaTec Combined for your slickline needs means selecting a partner dedicated to the success of your well operations. Our General Mechanical Slickline services are a reflection of our promise to deliver excellence in every aspect of our work, from the initial deployment of tools to the completion of maintenance tasks. Conclusion: Your Well's Performance, Our Commitment In conclusion, InWaTec Combined's General Mechanical Slickline services are essential for maintaining the high performance and integrity of your oil and gas wells. With our focus on precision, efficiency, and safety, we ensure that your maintenance operations are performed to the highest standards. Trust in the expertise and dedication of InWaTec Combined to keep your wells operating smoothly, safely, and efficiently.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Safeguarding Well Integrity with InWaTec Combined’s Advanced E-Line Casing Inspection Services At InWaTec Combined, we understand that maintaining the structural integrity of well casings is paramount to the uninterrupted production and long-term viability of any well. That’s why we are committed to offering comprehensive E-Line Casing Inspection Services, employing an array of sophisticated diagnostic techniques to detect and prevent casing failures before they compromise well operations. Casing failures can arise from a variety of factors, including deformation, physical wear, and corrosion. These issues, if not identified and addressed promptly, can lead to diminished well production or catastrophic failures. Recognizing the critical nature of this aspect of well maintenance, InWaTec Combined utilizes four industry-standard techniques for casing inspection, each offering unique insights into the condition of the wellbore structure: Cased-Hole Calipers: Our E-Line delivered cased-hole calipers provide precise measurements of the internal dimensions of the casing, identifying areas of deformation and wear that may not be immediately apparent. Flux-Leakage Tools: These tools detect flaws in the casing by identifying areas where magnetic flux leakage occurs, indicative of potential corrosion or metal loss. Electromagnetic Phase-Shift Tools: By measuring variations in electromagnetic fields, these tools can pinpoint defects within the casing structure, offering an early warning against integrity breaches. Ultrasonic Tools: Our ultrasonic inspection tools use high-frequency sound waves to assess the thickness of casing walls, detecting thinning that could lead to potential collapse. In addition to these methods, InWaTec Combined also employs ultrasonic radial-cement-evaluation devices and modified openhole-imaging devices. These specialized tools are invaluable in evaluating the casing for signs of internal or external metal loss—a critical step in preventing unexpected downtime and ensuring the integrity of the well. Our E-Line Casing Inspection Services are about more than just diagnostics; they provide a strategic approach to well maintenance. By utilizing these advanced tools, we offer a detailed assessment of the casing's condition, enabling operators to take preemptive action to rectify issues before they escalate into more significant problems. In choosing InWaTec Combined for your casing inspection needs, you are selecting a partner dedicated to the highest standards of well integrity and operational safety. We provide a comprehensive, E-Line delivered, diagnostic service that ensures your well remains productive, safe, and profitable for years to come. Trust in the precision of our technology and the expertise of our team to maintain the backbone of your well operations—because at InWaTec Combined, we believe that prevention is the key to sustainable production.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

InWaTec Combined: Clearing the Path to Performance with Gauge Cutter Services In the intricate arena of subsurface control, the clarity of the pathway is paramount. At InWaTec Combined, we specialize in pre-emptive solutions that pave the way for unimpeded operations. Our Gauge Cutter running services are a critical component of this approach, ensuring that your tubing is verified for freedom from obstruction, thus setting the stage for smooth running or pulling of subsurface controls. The Imperative for a Clear Tubing A gauge cutter is an essential tool in the well servicing toolkit. Its primary role is to confirm that the tubing through which subsurface controls will be run is clear of any blockages. InWaTec Combined’s gauge cutter services provide operators with the assurance they need before commencing critical operations. This step is not just precautionary; it is a strategic move to avoid non-productive time and to ensure that all subsequent interventions are conducted efficiently and effectively. The Gauge Cutter Advantage The design of our gauge cutters is a product of extensive research and practical field experience. The bottom shape of our tools is meticulously crafted to scratch, jar, and cut away common wellbore obstructions like paraffin, sand, or other deposits from the tubing wall. This cleaning action may necessitate several runs with gauge cutters of varying sizes, a process InWaTec Combined is well-equipped to manage. Versatile Applications for Comprehensive Assurance Our gauge cutter services are versatile and comprehensive. Often used to tag the top of landing nipples, Sliding Sleeve Doors (SSDs), or to ascertain the total well depth, our tools provide operators with a multi-faceted solution. Whether it’s for routine maintenance or critical well interventions, running a gauge cutter is a step that can save time and resources in the long run. Customized to Well Specifications Understanding that each well has its unique challenges, InWaTec Combined offers gauge cutters in various sizes and configurations. This customization allows for tailored applications, ensuring that whether the obstruction is due to paraffin buildup or sand deposition, we have the right tool for the job. Commitment to Operational Continuity Choosing InWaTec Combined for your gauge cutter services means selecting a partner dedicated to your operational continuity. Our tools and techniques are designed to facilitate a clear and smooth path for your subsurface controls, minimizing the risks of unexpected interruptions and maximizing your operation's productivity. A Clear Path Forward In summary, InWaTec Combined’s Gauge Cutter running services are an indispensable part of ensuring a successful and uninterrupted operation. By removing potential obstructions and verifying well integrity, we help you maintain operational efficiency. Trust InWaTec Combined to clear the path for your well’s performance, ensuring that every operation from the surface to the subsurface is conducted with confidence and precision.

Service

In Stock

Service

New

API

Land Freight

Specialized e-line tool services

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Empowering Operations with Advanced Solutions: InWaTec Combined’s Specialized E-line Tool Services At InWaTec Combined, we are dedicated to pushing the boundaries of operational excellence in the primary industries sector. Our specialized E-line tool services are meticulously crafted to address the unique challenges faced by operators, offering a suite of cutting-edge solutions that epitomize efficiency and redefine maintenance standards. In the heart of every successful operation lies the ability to adapt and innovate. InWaTec Combined’s specialized E-line tool services are the embodiment of this ethos. With our comprehensive array of tools, we empower operators to enhance well performance, streamline diagnostic processes, and execute interventions with unparalleled precision. Our services are not just about providing tools; they are about delivering a strategic advantage. Here’s a glimpse into our suite of specialized E-line tool services: Diagnostic Excellence: With the fast-paced evolution of well technologies, the need for accurate diagnostics has never been more critical. Our suite includes state-of-the-art logging tools that provide real-time data on well conditions, enabling operators to make informed decisions swiftly. Precision Interventions: Whether it's for perforation, plug setting, or cutting, our E-line tools are engineered for precision. We understand that each intervention is unique, and our tools are designed to deliver tailored solutions that ensure successful operations, every time. Maintenance and Recovery: Our maintenance tools, from scrapers to bailers, are selected for their reliability and effectiveness. When it comes to recovery operations, our fishing tools are second to none, providing the assurance that you can retrieve what is needed without undue delay. Customized Solutions: Recognizing that each operation has its distinct challenges, we offer customized tool services. Our expert team works closely with clients to develop and deploy tools that are specifically designed to meet the unique demands of their wells. InWaTec Combined is committed to innovation and excellence. Our specialized E-line tool services are continually evolving, incorporating the latest technologies and methodologies to stay ahead of industry demands. By partnering with us, operators gain access to a level of efficiency and maintenance capability that sets new industry benchmarks. We believe in a future where every operation is optimized for peak performance, and our specialized E-line tool services are a cornerstone of this vision. Choose InWaTec Combined for your operations, and experience the power of advanced tools and expert service that drive success.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Optimizing Reservoir Connectivity with InWaTec Combined's Precision Perforating Services In the intricate execution of oil and gas production, establishing a seamless flow path between the reservoir and the wellbore is vital for optimal extraction. At InWaTec Combined, we specialize in precision Perforating Services, a critical step towards ensuring that our clients’ wells are prolific producers. Perforating is a sophisticated process, and its execution is both an art and a science. It involves the precise creation of holes from the wellbore through the casing and cement sheath directly into the producing zone. This process is not merely about making openings; it's about strategically placing them to maximize flow rates and enhance the recovery of hydrocarbons. Our approach to perforating is methodical and tailored. We begin with an in-depth analysis of the well conditions and reservoir characteristics. This data informs our selection of perforating techniques, which range from the conventional to the cutting-edge, including shaped charges and advanced explosive materials that create clean, deep perforations with minimal damage to the formation. InWaTec Combined’s Perforating Services are about more than just punching holes; they are about delivering a highly controlled and effective conduit for hydrocarbons to travel from the reservoir to the surface. With our state-of-the-art technology and expertly engineered charges, we can ensure that the flow path is not just established, but optimized for the specific conditions of each well. Safety and precision are at the heart of our operations. We employ the latest in downhole technology, including real-time monitoring and electric line conveyance, to ensure that our perforations are executed with the highest degree of accuracy and control. This commitment to excellence and attention to detail is why InWaTec Combined is a leader in the field. By entrusting InWaTec Combined with your perforating needs, you are not just choosing a service provider—you are choosing a partner dedicated to enhancing the productivity of your wells. Our Perforating Services are integral to preparing your wellbore to be a strong link between the hidden riches of the reservoir and the energy needs of the world. Let us bring our expertise and precision to bear on your operations, and together, we can unlock the full potential of your assets.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Seamless Zone Isolation: InWaTec Combined’s E-line Bridge Plug Setting Services In the complex operations of oil and gas extraction, the ability to isolate zones within the wellbore is critical for effective production management and intervention. InWaTec Combined offers specialized E-line Bridge Plug Setting Services, utilizing state-of-the-art tools to achieve precise zonal isolation with both permanent and retrievable bridge plug options. Bridge plugs are essential elements in completion hardware, designed to provide robust seals both above and below the production tubing within the casing, liner, or wellbore wall. Their primary function is to isolate certain sections of the well, which is especially beneficial in wells with multiple producing zones or when specific zones need to be temporarily sealed off during interventions. Permanent Bridge Plugs: These are typically favored for their cost-effectiveness and superior sealing and gripping capabilities. Once set, they provide a dependable barrier, with metal slips or "slips" that anchor into the casing's inner diameter using sharpened, carburized teeth. The seal is completed with large cylindrical rubber elements, and in high-pressure environments, metal rings enhance the seal by preventing rubber extrusion. Retrievable Bridge Plugs: These plugs are the go-to solution when flexibility is required, such as during secondary recovery operations, well re-completions, or when there's a need to change out production tubing. Though they may have lower sealing and gripping capabilities compared to permanent options, their design allows for removal and reuse, providing significant operational versatility. Our E-line Bridge Plug Setting Services deploy these tools with precision. The plug is conveyed into the well via wireline—a method that provides real-time depth control and selectivity. Once at the target depth, an axial load is applied to the bridge plug to initiate the expansion of the slips and rubber elements, creating a secure seal against the casing. The setting mechanism can be activated hydraulically, mechanically, or with a controlled chemical charge, depending on the well conditions and client requirements. InWaTec Combined’s expertise ensures that the most appropriate setting method is chosen for each operation, considering the well's pressure environment, the desired duration of the plug setting, and the future plans for the well. By opting for InWaTec Combined’s E-line Bridge Plug Setting Services, operators benefit from a service that combines reliability with adaptability. Our commitment to leveraging advanced technologies with expert execution means that your well operations can proceed with confidence, knowing that each zone is isolated with the utmost precision. InWaTec Combined is dedicated to providing solutions that enhance operational efficiency and well integrity. Whether you require a permanent solution for long-term isolation or the flexibility of a retrievable plug for short-term interventions, our E-line Bridge Plug Setting Services are designed to meet your needs with precision, reliability, and cost-effectiveness.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Revolutionizing Geothermal Well Interventions: InWaTec Combined's Mini-Coil Services In the dynamic world of geothermal energy production, where the efficient management of well interventions is paramount, InWaTec Combined is pioneering with our Mini-Coil Services. Designed to navigate the unique challenges of geothermal wells, our Mini-Coil Tubing offers a versatile and high-pressure tolerant solution for fluid placements and well stimulation. Geothermal wells demand a delicate balance between precision and strength. Our Mini-Coiled Tubing services are tailored to meet these needs, providing an ideal solution for the small quantity placements of fluids that are often required in geothermal operations. Whether it's for precision acidizing, scale removal, or other chemical treatments, the Mini-Coil is an invaluable tool. Compact Power: Our Mini-Coiled Tubing is compact yet robust, designed to handle the high pumping pressures needed for effective interventions in geothermal wells. Its smaller diameter does not compromise its ability to withstand intense conditions underground. Efficiency in Production: Lifting wells into production efficiently is crucial for maintaining the economic viability of geothermal operations. The Mini-Coil facilitates this by enabling operators to deliver targeted treatments and interventions that can revitalize well performance. Tailored to Geothermal Needs: While traditional coiled tubing operations may be limited by flow and snubbing capabilities, our Mini-Coil Tubing is engineered to overcome these constraints, providing enhanced pressure handling that is especially beneficial in the high-temperature, high-pressure environments characteristic of geothermal wells. It's true that Mini-Coil Tubing has its limitations regarding flow and snub, but what it offers in return is the capacity to handle significantly higher pumping pressures. This attribute is particularly advantageous in geothermal applications where the subsurface conditions can be extreme. InWaTec Combined's commitment to innovation is further demonstrated by the integration of advanced monitoring technologies that accompany our Mini-Coil Services. Real-time data acquisition allows for precise control and assessment of the intervention process, ensuring that operations are not only successful but also conducted with an emphasis on safety and sustainability. In the realm of geothermal energy, where the right interventions can drastically enhance the output and longevity of wells, InWaTec Combined's Mini-Coil Services emerge as a clear choice for operators seeking to optimize their wells. Our services are a testament to our dedication to providing solutions that are both efficient and effective, reducing downtime and maximizing production. Partner with InWaTec Combined for your geothermal well needs and experience the next level of well intervention services. Let our Mini-Coil Tubing unlock the full potential of your geothermal operations, where precision meets power, and innovation drives production.

Service

In Stock

Service

New

API

Land Freight

Ensuring Production Integrity with InWaTec Combined's E-Line Tubing Inspection Services In the lifecycle of oil and gas wells, tubing integrity is fundamental to ensuring consistent production and operational safety. At InWaTec Combined, we offer specialized E-Line Tubing Inspection Services to preemptively identify and mitigate risks associated with tubing failure, utilizing state-of-the-art diagnostic techniques to safeguard your assets. Tubing failures, which can stem from deformation, physical wear, or corrosion, pose a significant threat to well integrity and production. Our advanced inspection services are designed to detect these issues early, enabling timely interventions that maintain continuous well performance. Our comprehensive suite of E-Line Tubing Inspection Services includes: Cased-Hole Calipers: These tools provide precise measurements of the internal diameter of tubing, detecting anomalies and changes that could indicate deformation or wear. Flux-Leakage Tools: Specialized for identifying defects in ferrous tubulars, these tools locate areas of metal loss or corrosion by detecting disruptions in magnetic flux. Electromagnetic Phase-Shift Tools: By measuring the changes in electromagnetic fields, these tools can effectively pinpoint areas of wall thickness changes due to corrosion or wear. Ultrasonic Tools: Employing high-frequency sound waves, these tools are adept at measuring tubing wall thickness, identifying areas at risk of thinning, which could lead to potential collapse. In addition to these, our E-Line Tubing Inspection Services also employ ultrasonic radial-cement-evaluation and modified openhole-imaging devices, which are particularly effective in assessing the condition of the tubing for signs of internal or external metal loss—a crucial step in preventing unexpected well shut-ins. At InWaTec Combined, we understand that the stakes are high when it comes to maintaining well integrity. Our E-Line Tubing Inspection Services are not just about identifying problems; they're about delivering peace of mind. By utilizing our advanced diagnostic tools, operators can rest assured that the integrity of their production tubing is being monitored with the utmost precision, allowing them to focus on maximizing output and efficiency. Choosing InWaTec Combined means partnering with a company that places a premium on innovation, safety, and reliability. Our commitment to excellence ensures that your operations benefit from the latest in inspection technology, delivered by a team of seasoned professionals. Trust us to provide the insights you need to keep your wells flowing safely and smoothly, today and into the future.

Envío:

Situado en:

![]() Canaweld Inc. en Vaughan

Canaweld Inc. en Vaughan

Discover the Powerhouse Welding Solution: Multiprocess 301-SL by Canaweld Are you in search of an industrial-grade welding machine that brings power, intelligence, and versatility to your oil and gas operations? Look no further than the Multiprocess 301-SL by Canaweld. This heavy-duty, synergetic, and intelligent welding machine is packed with advanced features, making it the ultimate choice for professional welders in the industry. Unleash Welding Excellence The Multiprocess 301-SL is an inverter-based arc welding power source optimized for MIG, Flux-Cored, Gasless Wires, TIG lift, and Stick welding, both in manual and synergic mode. Experience exceptional welding performance and a wide range of professional functions that meet the demands of industrial workshops. Its portability and ease of transport make it a reliable companion on any job site. Master Your Craft with Ease Equipped with a 5-inch color LCD display and various automatic controls, the Multiprocess 301-SL ensures quick and easy setup and operation. Both experienced welders and novices can operate the device effortlessly, reducing parameter setting time and increasing actual welding time. Synergic control provides pre-set weld parameters, improving usability and enabling operators of all skill levels to achieve precise results. Versatility at Your Fingertips No matter your welding requirements, the Multiprocess 301-SL has you covered. With the ability to perform MIG, Flux Cored, Gasless Wires, TIG lift, and Stick Welding, this machine adapts to various applications with ease. It is designed and tested to withstand the toughest conditions, ensuring reliability even in extreme heat of 104°F/40°C. Empowering Welding Precision The Multiprocess 301-SL boasts digital control of welding parameters based on the material or gas type and wire diameter, allowing for precise and efficient welding. Its manual polarity changeover feature supports the most common gas and gasless wires, Stick electrodes, and Lift TIG processes, providing flexibility in your welding tasks. Superior Wire Feeding Mechanism Canaweld's commitment to quality extends to the machine's wire feeding mechanism. The Multiprocess 301-SL features a professional and heavy-duty wire feeding system with 37mm rolls, a sealed, powerful, and durable wire feeder motor, and replaceable double groove rolls requiring no tools for replacements. Unmatched Customization Tailor your welding experience with adjustable voltage, wire speed, wave form, and burn back in the MIG process. In the TIG process, enjoy adjustable amperage, final slope, and post flow, while the Stick welding process allows for adjustable amperage, arc force, and material thickness selection. Designed for Convenience Canaweld understands the importance of easy access and movement during welding tasks. The Multiprocess 301-SL is equipped with flip doors and a specific mechanism to assist movement, allowing you to hold the doors in place at an angle for maximum ease of access. Additionally, the machine comes with lockable swivel casters for enhanced mobility. Reliable, Durable, and Worry-Free With Canaweld's comprehensive 3-year warranty, you can weld with confidence, knowing that your investment is protected. The Multiprocess 301-SL also includes two built-in eyebolts for lifting, making transportation and storage hassle-free. Join the Ranks of Industry Professionals Experience the power, precision, and versatility of the Multiprocess 301-SL by Canaweld. This welding powerhouse will elevate your oil and gas projects to new levels of efficiency and excellence. From novices to seasoned professionals, the Multiprocess 301-SL is the ultimate choice for welders who demand the best. Unlock your welding potential today with Canaweld. Invest in the future of welding technology and experience the unmatched performance of the Multiprocess 301-SL.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() Eleks en Toronto

Eleks en Toronto

ELEKS: Revolutionizing Energy Sector Through Big Data and AI Expertise The energy sector is undergoing a seismic shift, and at ELEKS, we're proud to be at the forefront of this transformation. Our unrivaled expertise in Big Data and artificial intelligence (AI) opens new avenues of efficiency and innovation for your organization. With a deep commitment to reshaping the energy landscape, we present you with a list of ten compelling benefits that our services can offer: 1. Data-Driven Decision-Making: Harness the power of data-driven insights. ELEKS' data modelling expertise and AI solutions empower you to make informed decisions that steer your organization towards success. 2. Streamlined Data Analytics: From diagnostic to predictive, our services streamline the entire spectrum of data analytics, providing clarity and actionable insights to support your strategic planning. 3. Swift Load-Flow Calculation: Embrace lightning-fast load-flow calculations powered by AI. Experience a significant reduction in calculation times, enabling quicker responses and better resource allocation. 4. Efficient Asset Management: Manage your energy assets with precision. Our AI-driven tools offer accurate asset insights that facilitate optimal utilization, maintenance planning, and resource allocation. 5. Risk Management Enhancement: Anticipate risks and mitigate them effectively. ELEKS' AI-based solutions help identify potential risks, enabling you to proactively address challenges and ensure continuity. 6. Innovation at Scale: ELEKS doesn't just adapt to change; we pioneer it. Our innovative approach ensures you stay ahead in an evolving energy landscape. 7. Personalized Solutions: Tailored to your organization's unique needs, our AI-powered offerings provide custom solutions that align seamlessly with your goals. 8. Technical Excellence: Expect precision and accuracy in every solution we deliver. Our team of experts ensures that you receive results of the highest technical caliber. 9. Collaborative Partnership: Partner with ELEKS to unlock your energy sector's potential. We collaborate closely with you, combining your industry knowledge with our technical prowess. 10. Future-Ready Resilience: With ELEKS, you're prepared for the future. Our AI solutions equip your organization to adapt, thrive, and excel as the energy sector evolves. At ELEKS, we're not just offering services; we're forging a path towards a more efficient, innovative, and sustainable energy sector. Join us in this journey of transformation as we leverage Big Data and AI to reshape the energy landscape. Trust ELEKS to empower your organization to make informed decisions, optimize operations, and drive success in the dynamic energy sector of tomorrow.

Service

Made to Order

Service

New

ISO

HDI 2021 Pressure Transmitter System

Pressure Transmitter![]() Houston Digital Instruments en Houston

Houston Digital Instruments en Houston

When it comes to precise and reliable pressure measurement, the HDI 2021 Pressure Transmitter System sets the standard for excellence. Built with the high-quality components that HDI is renowned for, this intrinsically safe, certified, solid-state 4-20mA transmitter ensures exceptional performance in even the most demanding applications. Tailored to Your Needs: The HDI 2021 is available in a variety of configurations, allowing customers to specify the housing that best suits their unique application requirements. With customisation options at your disposal, you can trust that the transmitter will seamlessly integrate into your operational setup. Complete Assembly for Easy Installation: Delivered as a complete assembly, the HDI 2021 Pressure Transmitter System is ready for quick and hassle-free installation. We understand the value of your time, which is why we provide a comprehensive solution that saves you effort and resources. Unparalleled Safety and Reliability: All HDI Transmitters are designed to provide unmatched safety, accuracy, reliability, and low maintenance for our users. With the 2021 Pressure Transmitter System, you can have peace of mind knowing that it meets the highest industry standards and is built to last. Versatility for Various Applications: The HDI 2021 can be customized not only for pressure measurement but also for load, force, and torque applications across different industries. Whether you are in oil and gas, manufacturing, or any other field, our team can work with you to tailor the system to your specific needs. Certifications You Can Trust: The HDI 2021 Pressure Transmitter System boasts certifications that ensure compliance and performance. It is CSA certified as Intrinsically Safe Class 1, Division 1, Groups A, B, C, and D. Additionally, an optional ATEX certification (II 1 G, Ex ia IIC T4) is available for enhanced safety in hazardous environments. Key Features: • Field repairable system, minimizing downtime and reducing maintenance costs • Wide pressure range options, including 5,000 psi, 6,000 psi, 10,000 psi, 16,000 psi, and 20,000 psi • Multiple connection types, such as 2" 1502, 2" 2002, 2" 2202, or flanged connections, providing flexibility for installation • 4-20mA output available, ensuring compatibility with your existing systems • Solid-state platform with no fluids or moving parts, guaranteeing long-term reliability and accuracy Trust HDI for Unmatched Performance: When it comes to pressure measurement, the HDI 2021 Pressure Transmitter System stands out as the pinnacle of quality and precision. Contact our experienced team today to discuss your specific application requirements and experience the HDI advantage. With our unwavering commitment to excellence, we deliver solutions that meet your needs and exceed your expectations. Houston Digital Instruments - Your Partner in Precision Measurement.

Buy

In Stock

Manufacturer

New

API

Air Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Precision Depth Control with InWaTec Combined's Casing Collar Locator Services Precise depth measurement is the linchpin of successful well completion and intervention. At InWaTec Combined, we recognize the pivotal role of accurate depth correlation in the lifecycle of a well, which is why we offer our specialized Casing Collar Locator (CCL) Services. These services are not just about measurement; they are about enhancing the precision of every operation that follows. The CCL is an essential tool in our suite of downhole diagnostic services, used to establish an accurate depth correlation between the casing collars and the open hole log of the well. This correlation is vital for a multitude of subsequent operations, particularly for the strategic placement of perforations and the depth assurance of wireline services within the cased hole. Typically run in tandem with a gamma ray, Cement Bond Log (CBL), or other cased-hole logging tools, our CCL services ensure that completion depths chosen from open hole logs are accurately transferred to the cased well environment. This step is critical because it anchors the location of future operations to a verified depth reference, ensuring that all interventions are performed at the intended stratigraphic intervals. The CCL log becomes a key depth control measurement, serving as a guide for precision perforating. It allows us to target the exact depth for the perforation guns, ensuring that we connect the wellbore to the hydrocarbon-bearing zones with pinpoint accuracy. This service is particularly crucial in complex wells where even small deviations can lead to significant complications. At InWaTec Combined, we understand that the integrity and success of cased-hole wireline services hinge on the reliability of depth measurements. Our CCL services provide a foundation of certainty upon which all subsequent interventions can confidently build. With our CCL technology, clients can expect a seamless transition from logging to completion, perforating, and beyond. Opting for InWaTec Combined's CCL Services means choosing a partner committed to precision and reliability. Our advanced tools, combined with our expert analysis, provide the clarity and assurance needed to execute well interventions with confidence. Ensure your operations are grounded in accuracy with InWaTec Combined, where every millimeter counts towards the success of your well.

Service

In Stock

Service

New

API

Land Freight

Xanthum Gum (Liquid and Powder)

Xanthum Gum![]() Cleanstream B.V. en Ter Apel

Cleanstream B.V. en Ter Apel

Introducing Xantham Gum from Cleanstream – the versatile solution for your drilling and completion needs. As a leader in providing innovative and environmentally responsible solutions for the oil and gas industry, Cleanstream is proud to offer this unique polymer for rheology modification, hole cleaning, and solids suspension. What sets Xantham Gum apart is its ability to provide excellent friction reduction – a feature that is unmatched by most other polymers in oilfield drilling and completion applications. Additionally, it can be used in most types of water-based fluids, making it an incredibly versatile product for your operations. Our in-house laboratory facilities allow us to determine the right approach to solve your specific problem. And at Cleanstream, we are committed to developing eco-friendly solutions for as many applications as possible. Whether you need Xantham Gum for a specific project or require our personnel and equipment for complete execution, we have you covered. Click on the datasheet for more information or contact us to learn how Xantham Gum can benefit your operations. Trust Cleanstream for innovative and sustainable solutions for your oil and gas needs.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

![]() Canaweld Inc. en Vaughan

Canaweld Inc. en Vaughan

Experience Precision and Professionalism with the TIG DC 202 Pulse-D Welding Machine At Canaweld, we understand the importance of precision and sleek design in welding, especially for industries like oil and gas, marine, aerospace, and medical. That's why we offer a wide range of TIG welders designed to give you the control necessary to achieve professional results with various parent metals. Our TIG welders are the ultimate choice for welders who demand excellence and quality in their work. Introducing the TIG DC 202 Pulse-D - Your Portable Powerhouse The TIG DC 202 Pulse-D is a welding machine that sets new standards in the industry. Portable, powerful, and versatile, it is the perfect tool for welders seeking exceptional TIG welds on stainless and mild steel or Stick welding. The professional pulse features, combined with HF start, make it an ideal companion for achieving high-quality welds, even on very thin steel, with no distortion. Unmatched Features for Unrivaled Performance At Canaweld, we believe in delivering welding machines that exceed expectations. The TIG DC 202 Pulse-D is packed with features that enhance your welding experience: • High Frequency (HF) for start, ensuring a smooth and efficient start to your welding projects. • Rigorously tested in (104°F/40°C) to guarantee optimal performance even in the toughest conditions. • Digital control of all welding parameters, giving you precise control over your welding process. • Dual control options: Amperage control accessible by both foot pedal and fingertip controls on the torch body, offering convenience and flexibility during welding. • Pulse TIG welding for better arc control and reduced workpiece deformation, resulting in professional welds on thin materials. • Exceptional welding characteristics in Stick mode with the most common rod in the market, adding versatility to your welding tasks. • Long-distance welding capability: Ability to use up to 165 feet (50 meters) leads without any power loss at the welding circuit, giving you freedom of movement on the job. • Digital adjustment of pre-gas, base current, welding current, slope up, pulse parameters, slope down, and post-gas with digital display for precise customization. • Arc Force automatically selects the best welding arc dynamics, optimizing your welding performance. • Visual welding current pre-setting ability for accurate and efficient parameter selection. • Fan cooled and thermally protected against overheating, ensuring durability and safety during operation. • Durable metal face panel, guaranteeing longevity and protection. • Generator compatible, providing versatility and adaptability for various worksites. Your Welding Excellence is Our Priority We take pride in our products, and the TIG DC 202 Pulse-D is no exception. To ensure your satisfaction and confidence in our welding machine, we offer a comprehensive 3-year warranty, protecting your investment and giving you peace of mind. Elevate Your Welding Experience with Canaweld Take control of your welding projects with precision and professionalism. Choose the TIG DC 202 Pulse-D from Canaweld and experience welding excellence like never before. Whether you're in the marine, aerospace, or medical industry, or any other field that demands top-tier welds, this welding machine will deliver unparalleled performance and superior results. Invest in the future of welding technology. Choose Canaweld, and unlock your welding potential with the TIG DC 202 Pulse-D. Experience precision, power, and professionalism in every weld.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() Nulux Networks en Edmonton

Nulux Networks en Edmonton

Revolutionizing Wireless Connectivity in the Oil and Gas Industry with Nulux Network Solutions In an era where instant and reliable connectivity is paramount, especially in the meticulous domain of the oil and gas industry, seamlessly integrated wireless networks are not a luxury but a necessity. Navigating through the intricate operational matrices and colossal data, Nulux Network Solutions proffers unparalleled WiFi setup services, ensuring your wireless connectivity is robust, reliable, and resilient. Nulux: A Vanguard in Wireless Solutions Through our profound expertise in devising wireless systems and infrastructure, Nulux has become synonymous with impeccable wireless communication links. Whether it’s through point-to-point or multipoint radio networks, tower construction/rigging, or mesh networks, our dedicated team ensures that geographical and physical impediments become inconsequential in your communication and data transmission endeavors. Wi-Fi Access Points: A Linchpin of Operational Efficacy Navigating through bustling work environments in the oil and gas sector necessitates the deployment of wireless networks that are not only widespread but also impeccable in terms of performance and reliability. With Nulux’s unparalleled experience in the design and deployment of wireless networks, seamless connectivity transcends your office and permeates every corner of your operation - whether it be the warehouse, facility floor, or field sites. Deciphering Point to Point and Multipoint Configurations In the context of wireless networking: Point to Point (P2P) networks furnish a direct linkage between two nodes, ensuring streamlined communication and data transmission between them. This configuration, touted for its enhanced security, due to the dedicated nature of the connection, and increased productivity, ensures your data travels securely and uninhibited from one point to another. Multipoint configurations, on the other hand, establish a connection amongst more than two points, with a single line shared amongst multiple nodes. This configuration can be particularly beneficial in scenarios that demand centralized data access across various points. The Nulux Promise: Connectivity Beyond Boundaries Tethering on our commitment to ensuring your operations are perpetually connected and data transmissions are ceaselessly secure and reliable, our WiFi setup services promise: Ubiquitous Connectivity: Ensuring every node, regardless of its geographical positioning, is perpetually connected. Robust Security: Safeguarding your data transmissions against potential cyber threats and ensuring they traverse through a secure network. Operational Efficiency: Through our WiFi setups, we ensure your operational matrix, be it documentation review, QA-QC, or project planning, is continually enhanced and refined. Cost-Effective Solutions: Ensuring your wireless network, whether it be a point to point or multipoint configuration, is not only operationally beneficial but also financially viable. In the intricate and operationally critical realm of the oil and gas industry, ensuring your wireless connectivity is not only robust but also reliable and secure, is paramount. With Nulux Network Solutions, you’re not merely adopting a WiFi setup; you’re embedding a network that promises operational excellence, secure data transmissions, and an enhanced operational matrix. Connect with Nulux today and ensure your operations are always connected, your data transmissions always secure, and your wireless network is always reliable.

Service

In Stock

Service

New

ISO

Injection Valve Subsurface Safety 4.48 inch

WI Valve![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

![]() Poseidon Robotics en Chandler

Poseidon Robotics en Chandler

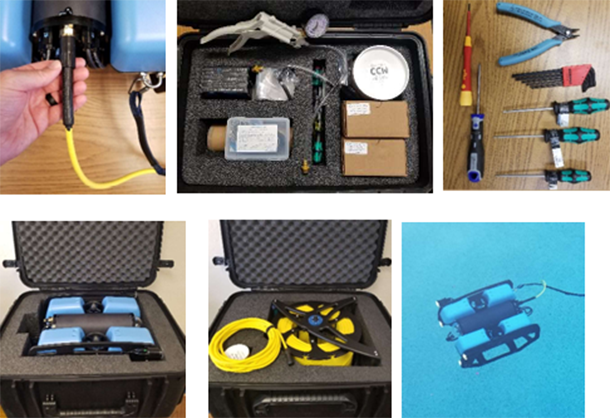

Unlock the Power of Deep-Water Connectivity with Poseidon's Modular Telemetry System Discover the Versatile Solution for Subsea Communications Diving into the depths of the ocean requires cutting-edge technology that can handle the challenges of the underwater world. Poseidon Robotics proudly presents the Modular Telemetry System (MTS) - a game-changing solution that will redefine the way you communicate with your remote underwater systems. The Bottleneck Breaker Trying to fit a bottle into a square space? Say goodbye to those limitations with the Poseidon MTS. Our rectangular design revolutionizes subsea telemetry, offering a multitude of Ethernet, video, and serial connections for deep-water ROVs, drills, and other systems. Tested to exceed 4,000m water depth, this system is built to perform even in the harshest subsea environments. Simplicity in Retrofitting Upgrading older ROVs and expanding their capabilities has never been easier. The MTS package provides everything you need to make use of a spare fiber connection and A/C or high voltage power. Retrofitting older ROVs with multiple sensors on a tooling skid or integrating custom equipment like geotechnical platforms has never been more streamlined. Compact Yet Powerful The Poseidon MTS boasts an impressive feature set while maintaining a compact size. Measuring at less than 2 feet long and only 5.5 inches wide, it's about the height of a coffee mug. But don't be fooled by its size; it packs a punch with up to 18 different accessory connections and half a kilowatt of onboard power, all rated to a remarkable 4,000 meters depth. Engineering Excellence Using modern 7075 Aluminum alloy and employing advanced FEA modeling and testing, we've ensured the MTS is built to withstand the most challenging subsea conditions. Its robust construction guarantees durability and reliability, offering peace of mind during your underwater missions. Customization and Expansion The MTS's versatility knows no bounds. It replaces larger telemetry bottles, offering ample space for multiple pieces of equipment. Whether you need a full telemetry system with instrument power or wish to expand your ROV skids, the MTS has got you covered. Unmatched Connectivity The MTS Subsea Mux is the heart of the system, featuring: • Depth Rating: Dive confidently up to 4,000 meters, exploring new depths with ease. • Multiple Connectivity: Enjoy 16x serial ports, 2x PAL/NTSC video, and 1x Ethernet, providing you with a wide range of communication options. • Onboard Power: Boasting 500W of onboard regulated 26/12VDC power, it ensures your remote sensors receive the power they need. Seamless Surface Integration The Surface Rack complements the MTS with its 19-inch Rack 2U chassis and RJ45 outputs, delivering low latency connections for a smooth surface experience. Powerful Transformation with MTSX If you require a full telemetry system with instrument power, our compact MTSX transformer assembly is the perfect addition. Featuring an integrated umbilical gland and oil-filled 3kW transformer with 3kV input, it provides unparalleled performance. Explore with Confidence Poseidon Robotics empowers you to explore the depths with confidence. With the Modular Telemetry System by your side, you have the keys to unlocking new subsea possibilities. Learn More Today To discover how the Poseidon Modular Telemetry System can elevate your subsea operations, reach out to us and join the ranks of industry leaders who trust the future of deep-water communications with Poseidon Robotics. Dive Deeper, Go Farther.

Buy

In Stock

Manufacturer

New

ASME

Air Freight

Onshore Electric Line Services

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Revolutionizing Wellbore Diagnostics with InWaTec Combined's Onshore E-Line Services In the world of oil and gas exploration and production, knowledge is power—and power lies in the data. At InWaTec Combined, we understand that the foundation of effective well servicing is the precision and reliability of information obtained from deep within the Earth. That's where our Onshore Electric Line (E-Line) services come into play, a game-changer in the realm of wellbore diagnostics. An E-Line is, in essence, an electric cable capable of performing extraordinary tasks. Lowered into the wellbore, this lifeline serves as a crucial conduit between the heart of the well and the watchful eyes of our engineers. Its primary function is to transmit data regarding wellbore conditions, a task it performs with exceptional efficiency and accuracy. The brilliance of the E-Line service lies in its simplicity and its capability. As it descends through the geological layers, the e-line gathers critical data through logging activities, painting a clear and comprehensive picture of the well's status. This information is not just data; it is a narrative of the well's health, productivity, and potential. Our E-Line services are not merely about data collection; they are about enabling informed decision-making that can lead to enhanced production efficiency, increased safety, and minimized environmental impact. With precise information, interventions can be smarter, quicker, and more effective, leading to a significant reduction in downtime and operational costs. InWaTec Combined's commitment to excellence in E-Line services is unwavering. We invest in cutting-edge technology and the continuous training of our specialists to ensure that our clients receive the most reliable and advanced diagnostic services available. We're not just service providers; we're partners in your quest to unlock the full potential of your assets. In a sector where every decision counts, InWaTec Combined's Onshore Electric Line services stand as your assurance of precision, reliability, and insight. Let us illuminate the depths of your wellbore with data that drives success.

Service

In Stock

Service

New

API

Land Freight

Coiled Tubing Mechanical Dimple Tool

MDT, Mechanical Dimple Tool![]() Marlin Oil Tools en Calgary

Marlin Oil Tools en Calgary