¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

Single Stage Turbine

También conocido como:

Steam Turbine, TurbineBuy

Made to Order

Manufacturer

New

ISO

Air Freight

Título:

API-611 Steam TurbineNúmero de modelo:

API-611Disponibilidad:

Made to OrderTiempo de entrega (semanas):

52 Weeks

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Para información sobre productos o servicios, personalización u otras preguntas

Título

API-611 Steam TurbineTambién conocido como

Steam Turbine, TurbineNúmero de modelo

API-611Disponibilidad

Made to OrderTiempo de entrega (semanas)

52 WeeksTipo de transacción

Spec_transactionPrecio

Request for QuoteCondición

NewMaterial

SteelPeso

Various weights available kgNombre de la marca

KesselsUbicación

IndiaTipo de compañía

ManufacturerGarantía de calidad

ISOEnvío

Air FreightNotas

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

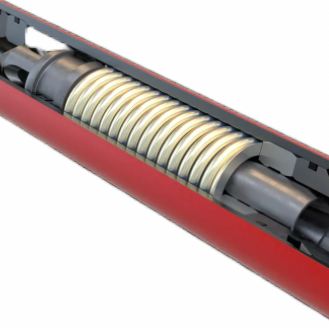

Introducing the Kessels MS-32 Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the dynamic world of industrial steam turbines, efficiency, reliability, and flexibility are paramount. At Kessels Steam Turbines, we understand the unique needs of the oil and gas industry, where the demand for steam is relentless. That's why we are proud to introduce our MS-32 Multistage Steam Turbine – the pinnacle of back-pressure turbine technology. The Power of Back Pressure Turbines Back pressure turbines have long been a cornerstone of industrial steam applications, and they come in both single-stage and multi-stage options. These turbines serve as the vital link between the boiler unit and the process steam header. In environments where a copious amount of steam is required, back pressure turbines shine. Straight-Back Pressure for Maximum Efficiency What sets back pressure turbines apart is their straight-back pressure nature. This design allows for the efficient utilization of exhaust steam to meet process demands. The electrical power generated during the process is consumed precisely as needed, making it an energy-efficient choice. Applications Galore Our MS-32 Multistage Steam Turbine is a versatile powerhouse, ideally suited for a wide range of applications: Drive Applications: Commonly employed in the oil and gas industry, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and many more. Power Generation Applications: Utilized to generate electricity by powering generators, offering a clean and sustainable energy solution. Bleed Back-Pressure Steam Turbines For scenarios where controlled extraction of steam within a medium pressure range is necessary, our turbines come equipped with bleed points. This feature allows for steam extraction at low volume steam demands, making it perfect for applications with high tolerance for pressure variations. Extraction Back-Pressure Steam Turbines When the process steam demand volume is substantial, and tolerance for pressure variations is minimal, our steam turbines with controlled extraction vents step up to the plate. Operating under intermediate pressure levels, they ensure a consistent and reliable steam supply. Why Choose Kessels? When you choose Kessels Steam Turbines, you're choosing more than just a product – you're choosing a legacy of excellence. With a history spanning decades, we have continuously pushed the boundaries of steam turbine technology. Our MS-32 Multistage Steam Turbine is a testament to our unwavering commitment to innovation, performance, and customer satisfaction. Unmatched Benefits of the MS-32 Multistage Steam Turbine: Energy Efficiency: Our turbines maximize the use of exhaust steam, minimizing wastage and lowering energy costs. Reliability: Built with precision and rigorously tested, the MS-32 ensures uninterrupted operations, even in demanding environments. Versatility: From drive applications to power generation, this turbine adapts to your needs with ease. Eco-Friendly: Harnessing the power of steam for electricity generation reduces carbon emissions, contributing to a greener future. Responsive Support: Our team of experts is always at your service, ready to assist with installation, maintenance, and troubleshooting. Upgrade to Excellence Today In the competitive world of the oil and gas industry, every advantage counts. Make the smart choice by upgrading to the Kessels MS-32 Multistage Steam Turbine – the epitome of efficiency, reliability, and sustainability. Contact us today to learn more about how our turbine can revolutionize your operations and propel your success into the future. Your journey to unparalleled performance starts here, with Kessels Steam Turbines.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 EB Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Power and Precision with the Kessels MS-42 EB Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the high-stakes world of the oil and gas industry, precision and performance are non-negotiable. That's why, at Kessels Steam Turbines, we're proud to introduce our cutting-edge MS-42 EB Multistage Steam Turbine – a powerhouse engineered to redefine excellence in back-pressure turbine technology. Mastering Back-Pressure Turbines Back pressure turbines have been the workhorses of industrial steam applications for decades, and our MS-42 EB takes their capabilities to new heights. Whether it's single-stage or multi-stage options, these turbines serve as the critical bridge between the boiler unit and the process steam header, revolutionizing steam utilization and power generation. Efficiency Redefined Our MS-42 EB Multistage Steam Turbine boasts the hallmark of back pressure turbines: their straight-back pressure nature. This design ensures the efficient harnessing of exhaust steam, meeting process demands with unparalleled precision. Every ounce of electrical power generated is consumed as per the process steam demand, offering unmatched efficiency. Applications Beyond Boundaries At Kessels, we understand that diverse industries have unique demands. That's why our MS-42 EB Multistage Steam Turbine excels in a wide range of applications: Drive Applications: Embrace the power of our turbine in oil and gas operations, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and more. Wherever drive power is needed, Kessels delivers. Power Generation Applications: Elevate your sustainability game by using our turbine to generate electricity, powering generators with clean and efficient steam energy. Bleed Back-Pressure Steam Turbines Our commitment to versatility is evident in the design of the MS-42 EB. With built-in bleed points, uncontrolled extraction vents enable steam extraction within a medium pressure range. This feature proves invaluable in situations where bleeding steam is required at low volume steam demands and when there's a high tolerance for pressure variations. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines When your process steam demand volume is substantial, and you can't compromise on pressure variations, our steam turbines with controlled extraction vents come to the rescue. These turbines operate under intermediate pressure levels, ensuring a steady and reliable steam supply that your operations can depend on. Why Choose Kessels? Choosing Kessels Steam Turbines means choosing a legacy of excellence, innovation, and reliability. Our MS-42 EB Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization and minimize wastage with our precision-engineered turbine. Reliability Redefined: Rigorously tested and built with unwavering precision, the MS-42 EB ensures your operations run seamlessly. Unparalleled Versatility: Adapt to changing needs effortlessly, whether it's drive applications or eco-friendly power generation. Sustainability at Its Core: Harness the power of steam for electricity generation, reducing your carbon footprint and contributing to a greener future. Expert Support: Our team of specialists is always at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42 EB Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you towards a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

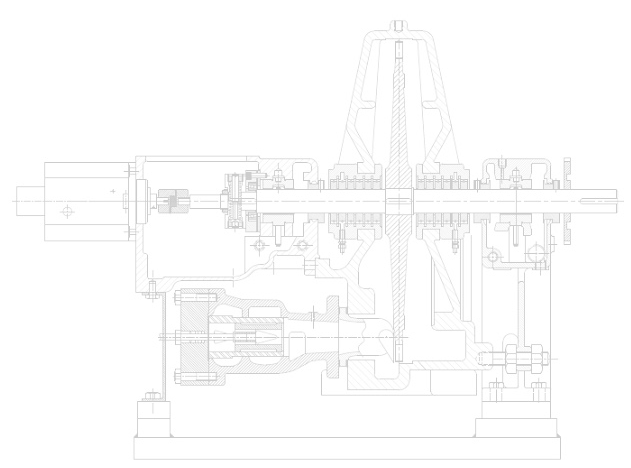

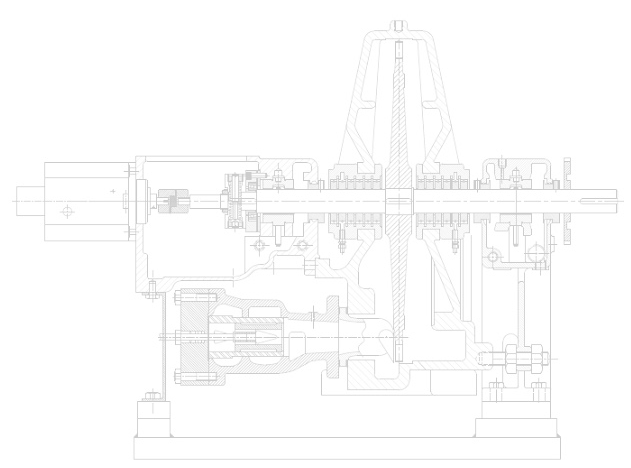

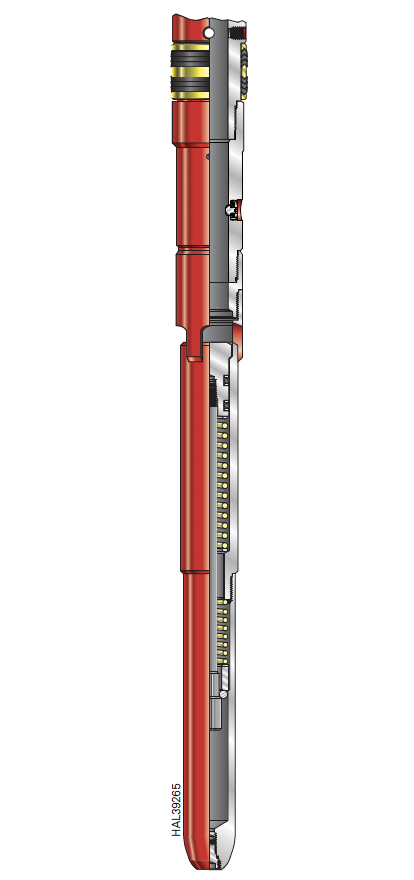

Elevate Your Operations with Kessels API-611 Compliant Steam Turbine: Where Precision Meets Excellence In the demanding realm of the oil and gas industry, precision, reliability, and adherence to standards are paramount. Kessels Steam Turbines takes pride in being a premier supplier of Steam Turbines that not only comply with but exceed the rigorous API-611 standards for general-purpose steam turbines. Setting New Standards in Steam Turbine Excellence Kessels Steam Turbines are at the forefront of driving pumps, fans, and compressors in Oil Refineries across the Middle East, India, and South East Asia. These turbines stand as testaments to our unwavering commitment to adhering to stringent design engineering practices set by oil giants and discerning end customers alike. Distinguishing Features of Kessels API-611 Single Stage Steam Turbines: Meets & Exceeds API-611 Standard: Our turbines not only meet but go beyond the API-611 standard, ensuring top-notch performance and reliability. Direct Drive Oil Relay Governors: Equipped with provisions for Direct Drive Oil relay constant speed governors conforming to NEMA class 'A' & NEMA class 'D'. Over Speed Mechanical Trip: Safety is paramount, and our turbines come with an over-speed mechanical trip with safety shut-off as standard. Versatile Gland Sealing: Gland sealing is achieved through carbon rings (up to six, removable), labyrinths, or mechanical steam seals. We offer the flexibility of choosing any combination of these three options. Impulse-Type Wheels: Provision for Single disc single-row, and Single disc two-row Curtis impulse-type wheels made of forged steel. Built-in Steam Strainer: As a standard feature, our turbines include a built-in steam strainer that is removable for your convenience. Versatile Support: Our turbines can be centerline or foot-mounted, offering flexibility in installation. Solenoid Trips: Provision for solenoid trips for remote shutdowns comes as standard, ensuring safety and control. Suitable for High Pressures: Built to handle high inlet and exhaust steam pressures, our turbines are robust and reliable. Horizontal and Vertical Orientation: Choose between horizontal and vertical shaft orientation to suit your specific needs. These features are a testament to our unwavering commitment to ensuring that customers can operate Kessels API-611 compliant Steam Turbines with complete peace of mind for their mechanical driving needs. Choose Kessels for Unparalleled Excellence Choosing Kessels Steam Turbines is a choice for excellence, precision, and reliability. Our API-611 Compliant Steam Turbines not only meet industry standards but surpass them, ensuring the highest levels of performance and safety for your operations. Empower Your Operations with Kessels In the competitive landscape of the oil and gas industry, precision and reliability are non-negotiable. Elevate your operations with the Kessels API-611 Compliant Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-201 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Operations with the Kessels MS-201 Multistage Steam Turbine: Unmatched Power and Efficiency In the ever-evolving world of the oil and gas industry, precision and performance are paramount. At Kessels Steam Turbines, we're proud to introduce the MS-201 Multistage Steam Turbine, an engineering marvel that redefines excellence in steam turbine technology. Mastering Back-Pressure Turbines Back pressure turbines are the backbone of industrial steam applications, and our MS-201 Multistage Steam Turbine takes them to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines serve as the critical link between boiler units and process steam headers, revolutionizing steam utilization and electricity generation. Efficiency That Sets a New Standard At the heart of the MS-201 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning precisely with process demands. Every unit of electrical power generated is consumed as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-201 turbine is not just a machine; it's a versatile powerhouse ready to excel in diverse applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines Kessels understands that adaptability is key. Our MS-201 turbine features built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are critical. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents shine. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-201 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in substantial cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the harshest industrial environments. Unparalleled Versatility: Adapt effortlessly to changing needs, whether for drive applications or eco-friendly power generation, with the confidence that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unlock Energy Efficiency with Kessels API-611 Steam Turbine: The Ultimate PRV Replacement Solution In the dynamic world of industrial applications, energy efficiency is the cornerstone of sustainable operations. Kessels Steam Turbines is proud to offer a groundbreaking solution that replaces traditional Pressure Reducing Valves (PRV) with our robust, reliable, and highly efficient API-611 Steam Turbines. Revolutionizing Energy Efficiency Kessels Single Stage Steam Turbines are tailor-made to handle Saturated Steam at low inlet pressures, harnessing the pressure drop of steam to generate power through the turbine via geared or gearless Turbo Generator set solutions. Choice in Generators for Your Unique Needs Our Turbo Generator sets can be configured with either Induction Generators or Synchronous Generators, catering to the specific requirements of our customers. Energy Recovery at Its Best Kessels Industrial PRV replacement solutions are designed to recover wasted energy by reducing steam pressure through our steam turbines, surpassing the limitations of traditional PRVs. This not only generates valuable power for industrial use but also caters to the process steam requirement of the industry. The result? Drastically reduced operational costs and reduced reliance on the grid and other more expensive power sources. Balancing Act: PRV and Power Generation Kessels Single Stage Steam Turbines are ingeniously designed to enable customers to enjoy the full benefits of a PRV system while simultaneously generating useful power. This equilibrium is achieved without compromising the stability or safety of the system or their setup. Maximizing Power Output For optimum performance, Kessels offers the option of Multiple Valve Operated Steam Turbines. These turbines ensure customers get maximum power output, even at partial loads and varying steam flows. Our valves, available in the Single Stage Steam Turbine range, can be controlled automatically through the special PLC-based governing system provided by Kessels for turbines coupled to Induction Generators. Versatile Powerhouses Kessels API-611 Steam Turbines are versatile, highly efficient, rugged, and robust. They boast single disc one-row and two-row Curtis impulse-type wheels, making them suitable for a wide range of industrial applications. Additionally, these turbines can be retrofitted to any existing boiler setup, making them a versatile choice for various installations. Key Features: Versatile and highly efficient. Single disc one-row and two-row Curtis impulse-type wheels. Retrofittable to existing boilers. Operates efficiently with high exhaust steam pressures. PLC-based control panel with HMI screen for ease of use (optional). Compatible with both Induction and Synchronous Generators. Operates in solo mode or synchronized mode. Can be synchronized with the grid and/or other power sources. Reduces operational costs with a short payback period. Quick startup times and option for complete automatic operation. Choose Kessels for a Sustainable Future Elevate your industrial operations with the Kessels API-611 Steam Turbine, the ultimate PRV replacement solution that combines energy efficiency, reliability, and versatility. Contact us today to discover how our turbine can revolutionize your energy management and lead you toward unprecedented success.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Operations with Kessels API-611 Compliant Steam Turbine: Where Precision Meets Excellence In the demanding realm of the oil and gas industry, precision, reliability, and adherence to standards are paramount. Kessels Steam Turbines takes pride in being a premier supplier of Steam Turbines that not only comply with but exceed the rigorous API-611 standards for general-purpose steam turbines. Setting New Standards in Steam Turbine Excellence Kessels Steam Turbines are at the forefront of driving pumps, fans, and compressors in Oil Refineries across the Middle East, India, and South East Asia. These turbines stand as testaments to our unwavering commitment to adhering to stringent design engineering practices set by oil giants and discerning end customers alike. Distinguishing Features of Kessels API-611 Single Stage Steam Turbines: Meets & Exceeds API-611 Standard: Our turbines not only meet but go beyond the API-611 standard, ensuring top-notch performance and reliability. Direct Drive Oil Relay Governors: Equipped with provisions for Direct Drive Oil relay constant speed governors conforming to NEMA class 'A' & NEMA class 'D'. Over Speed Mechanical Trip: Safety is paramount, and our turbines come with an over-speed mechanical trip with safety shut-off as standard. Versatile Gland Sealing: Gland sealing is achieved through carbon rings (up to six, removable), labyrinths, or mechanical steam seals. We offer the flexibility of choosing any combination of these three options. Impulse-Type Wheels: Provision for Single disc single-row, and Single disc two-row Curtis impulse-type wheels made of forged steel. Built-in Steam Strainer: As a standard feature, our turbines include a built-in steam strainer that is removable for your convenience. Versatile Support: Our turbines can be centerline or foot-mounted, offering flexibility in installation. Solenoid Trips: Provision for solenoid trips for remote shutdowns comes as standard, ensuring safety and control. Suitable for High Pressures: Built to handle high inlet and exhaust steam pressures, our turbines are robust and reliable. Horizontal and Vertical Orientation: Choose between horizontal and vertical shaft orientation to suit your specific needs. These features are a testament to our unwavering commitment to ensuring that customers can operate Kessels API-611 compliant Steam Turbines with complete peace of mind for their mechanical driving needs. Choose Kessels for Unparalleled Excellence Choosing Kessels Steam Turbines is a choice for excellence, precision, and reliability. Our API-611 Compliant Steam Turbines not only meet industry standards but surpass them, ensuring the highest levels of performance and safety for your operations. Empower Your Operations with Kessels In the competitive landscape of the oil and gas industry, precision and reliability are non-negotiable. Elevate your operations with the Kessels API-611 Compliant Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 E Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Experience Unmatched Efficiency with the Kessels MS-42E Extraction Condensing Steam Turbine: Your Power and Steam Solution In the fast-paced world of the oil and gas industry, precision, reliability, and efficiency are the cornerstones of success. Kessels Steam Turbines is proud to introduce the MS-42E Extraction Condensing Steam Turbine, a technological marvel designed to exceed your expectations and redefine excellence in steam turbine technology. Mastering Extraction Condensing Turbines Extraction condensing turbines are the beating heart of industries where a constant pressure steam flow is essential for various processes. The MS-42E shares constructional characteristics with condensing turbines, making it the ideal choice when you need a reliable source of constant pressure steam for your operations. Efficiency at Its Finest What sets the MS-42E apart is its ability to inject low-pressure steam from the second admission valve chest, efficiently utilizing available plant resources to meet power demands. This makes our turbine a vital player in co-generation scenarios, where it caters to both the power and steam requirements of your process plant. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is crucial, the MS-42E shines. This turbine ensures that your power generation remains steady, providing a reliable foundation for your operations. The Ultimate in Versatility At Kessels, we understand that every industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-42E is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines is not just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-42E Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Utilize low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Built with precision and rigorously tested, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience steady power generation, regardless of variations in process steam demands, ensuring your operations run smoothly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with confidence in Kessels' expertise. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42E Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-251EC Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unlock Unparalleled Efficiency with the Kessels MS-251 EC Extraction Condensing Steam Turbine: Where Precision Meets Power In the ever-evolving landscape of the oil and gas industry, precision, reliability, and sustainability reign supreme. Kessels Steam Turbines is proud to introduce the MS-251 EC Extraction Condensing Steam Turbine, a technological marvel that redefines excellence in steam turbine technology. Mastery of Extraction Condensing Turbines Extraction condensing turbines are the backbone of industries demanding a constant pressure steam flow for diverse processes. The MS-251 EC shares structural characteristics with condensing turbines, making it the ideal choice when you need a dependable source of constant pressure steam for your operations. Efficiency Perfected What sets the MS-251 EC apart is its remarkable capability to inject low-pressure steam from the second admission valve chest. This ingenious feature optimizes the utilization of available plant resources to meet power demands, making our turbine an indispensable asset in co-generation scenarios. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is paramount, the MS-251 EC excels. This turbine ensures your power generation remains steady, providing a rock-solid foundation for your operations. Ultimate Versatility At Kessels, we understand that each industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-251 EC is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines isn't just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-251 EC Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Harness low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience uninterrupted power generation, regardless of variations in process steam demands, ensuring your operations run seamlessly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with the confidence that Kessels' expertise provides. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive landscape of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-251 EC Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-201 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Operations with the Kessels MS-201 Multistage Steam Turbine: Unmatched Power and Efficiency In the ever-evolving world of the oil and gas industry, precision and performance are paramount. At Kessels Steam Turbines, we're proud to introduce the MS-201 Multistage Steam Turbine, an engineering marvel that redefines excellence in steam turbine technology. Mastering Back-Pressure Turbines Back pressure turbines are the backbone of industrial steam applications, and our MS-201 Multistage Steam Turbine takes them to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines serve as the critical link between boiler units and process steam headers, revolutionizing steam utilization and electricity generation. Efficiency That Sets a New Standard At the heart of the MS-201 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning precisely with process demands. Every unit of electrical power generated is consumed as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-201 turbine is not just a machine; it's a versatile powerhouse ready to excel in diverse applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines Kessels understands that adaptability is key. Our MS-201 turbine features built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are critical. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents shine. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-201 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in substantial cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the harshest industrial environments. Unparalleled Versatility: Adapt effortlessly to changing needs, whether for drive applications or eco-friendly power generation, with the confidence that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unlock Energy Efficiency with Kessels API-611 Steam Turbine: The Ultimate PRV Replacement Solution In the dynamic world of industrial applications, energy efficiency is the cornerstone of sustainable operations. Kessels Steam Turbines is proud to offer a groundbreaking solution that replaces traditional Pressure Reducing Valves (PRV) with our robust, reliable, and highly efficient API-611 Steam Turbines. Revolutionizing Energy Efficiency Kessels Single Stage Steam Turbines are tailor-made to handle Saturated Steam at low inlet pressures, harnessing the pressure drop of steam to generate power through the turbine via geared or gearless Turbo Generator set solutions. Choice in Generators for Your Unique Needs Our Turbo Generator sets can be configured with either Induction Generators or Synchronous Generators, catering to the specific requirements of our customers. Energy Recovery at Its Best Kessels Industrial PRV replacement solutions are designed to recover wasted energy by reducing steam pressure through our steam turbines, surpassing the limitations of traditional PRVs. This not only generates valuable power for industrial use but also caters to the process steam requirement of the industry. The result? Drastically reduced operational costs and reduced reliance on the grid and other more expensive power sources. Balancing Act: PRV and Power Generation Kessels Single Stage Steam Turbines are ingeniously designed to enable customers to enjoy the full benefits of a PRV system while simultaneously generating useful power. This equilibrium is achieved without compromising the stability or safety of the system or their setup. Maximizing Power Output For optimum performance, Kessels offers the option of Multiple Valve Operated Steam Turbines. These turbines ensure customers get maximum power output, even at partial loads and varying steam flows. Our valves, available in the Single Stage Steam Turbine range, can be controlled automatically through the special PLC-based governing system provided by Kessels for turbines coupled to Induction Generators. Versatile Powerhouses Kessels API-611 Steam Turbines are versatile, highly efficient, rugged, and robust. They boast single disc one-row and two-row Curtis impulse-type wheels, making them suitable for a wide range of industrial applications. Additionally, these turbines can be retrofitted to any existing boiler setup, making them a versatile choice for various installations. Key Features: Versatile and highly efficient. Single disc one-row and two-row Curtis impulse-type wheels. Retrofittable to existing boilers. Operates efficiently with high exhaust steam pressures. PLC-based control panel with HMI screen for ease of use (optional). Compatible with both Induction and Synchronous Generators. Operates in solo mode or synchronized mode. Can be synchronized with the grid and/or other power sources. Reduces operational costs with a short payback period. Quick startup times and option for complete automatic operation. Choose Kessels for a Sustainable Future Elevate your industrial operations with the Kessels API-611 Steam Turbine, the ultimate PRV replacement solution that combines energy efficiency, reliability, and versatility. Contact us today to discover how our turbine can revolutionize your energy management and lead you toward unprecedented success.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 E Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Experience Unmatched Efficiency with the Kessels MS-42E Extraction Condensing Steam Turbine: Your Power and Steam Solution In the fast-paced world of the oil and gas industry, precision, reliability, and efficiency are the cornerstones of success. Kessels Steam Turbines is proud to introduce the MS-42E Extraction Condensing Steam Turbine, a technological marvel designed to exceed your expectations and redefine excellence in steam turbine technology. Mastering Extraction Condensing Turbines Extraction condensing turbines are the beating heart of industries where a constant pressure steam flow is essential for various processes. The MS-42E shares constructional characteristics with condensing turbines, making it the ideal choice when you need a reliable source of constant pressure steam for your operations. Efficiency at Its Finest What sets the MS-42E apart is its ability to inject low-pressure steam from the second admission valve chest, efficiently utilizing available plant resources to meet power demands. This makes our turbine a vital player in co-generation scenarios, where it caters to both the power and steam requirements of your process plant. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is crucial, the MS-42E shines. This turbine ensures that your power generation remains steady, providing a reliable foundation for your operations. The Ultimate in Versatility At Kessels, we understand that every industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-42E is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines is not just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-42E Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Utilize low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Built with precision and rigorously tested, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience steady power generation, regardless of variations in process steam demands, ensuring your operations run smoothly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with confidence in Kessels' expertise. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42E Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 EB Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Power and Precision with the Kessels MS-42 EB Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the high-stakes world of the oil and gas industry, precision and performance are non-negotiable. That's why, at Kessels Steam Turbines, we're proud to introduce our cutting-edge MS-42 EB Multistage Steam Turbine – a powerhouse engineered to redefine excellence in back-pressure turbine technology. Mastering Back-Pressure Turbines Back pressure turbines have been the workhorses of industrial steam applications for decades, and our MS-42 EB takes their capabilities to new heights. Whether it's single-stage or multi-stage options, these turbines serve as the critical bridge between the boiler unit and the process steam header, revolutionizing steam utilization and power generation. Efficiency Redefined Our MS-42 EB Multistage Steam Turbine boasts the hallmark of back pressure turbines: their straight-back pressure nature. This design ensures the efficient harnessing of exhaust steam, meeting process demands with unparalleled precision. Every ounce of electrical power generated is consumed as per the process steam demand, offering unmatched efficiency. Applications Beyond Boundaries At Kessels, we understand that diverse industries have unique demands. That's why our MS-42 EB Multistage Steam Turbine excels in a wide range of applications: Drive Applications: Embrace the power of our turbine in oil and gas operations, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and more. Wherever drive power is needed, Kessels delivers. Power Generation Applications: Elevate your sustainability game by using our turbine to generate electricity, powering generators with clean and efficient steam energy. Bleed Back-Pressure Steam Turbines Our commitment to versatility is evident in the design of the MS-42 EB. With built-in bleed points, uncontrolled extraction vents enable steam extraction within a medium pressure range. This feature proves invaluable in situations where bleeding steam is required at low volume steam demands and when there's a high tolerance for pressure variations. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines When your process steam demand volume is substantial, and you can't compromise on pressure variations, our steam turbines with controlled extraction vents come to the rescue. These turbines operate under intermediate pressure levels, ensuring a steady and reliable steam supply that your operations can depend on. Why Choose Kessels? Choosing Kessels Steam Turbines means choosing a legacy of excellence, innovation, and reliability. Our MS-42 EB Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization and minimize wastage with our precision-engineered turbine. Reliability Redefined: Rigorously tested and built with unwavering precision, the MS-42 EB ensures your operations run seamlessly. Unparalleled Versatility: Adapt to changing needs effortlessly, whether it's drive applications or eco-friendly power generation. Sustainability at Its Core: Harness the power of steam for electricity generation, reducing your carbon footprint and contributing to a greener future. Expert Support: Our team of specialists is always at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42 EB Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you towards a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-201EC Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Energy Solutions with the Kessels MS-201 EC Extraction Condensing Steam Turbine: Efficiency Perfected In the dynamic world of the oil and gas industry, precision, performance, and sustainability are non-negotiable. Kessels Steam Turbines is proud to introduce the MS-201 EC Extraction Condensing Steam Turbine, a technological marvel that sets new standards in steam turbine excellence. Mastering Extraction Condensing Turbines Extraction condensing turbines are the lifeline of industries requiring a constant pressure steam flow for diverse processes. The MS-201 EC shares structural characteristics with condensing turbines, making it the ideal choice when you need a reliable source of constant pressure steam for your operations. Efficiency at Its Pinnacle What distinguishes the MS-201 EC is its remarkable capability to inject low-pressure steam from the second admission valve chest. This ingenious feature optimizes the utilization of available plant resources to meet power demands, making our turbine an indispensable asset in co-generation scenarios. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is paramount, the MS-201 EC shines. This turbine ensures your power generation remains steady, providing a rock-solid foundation for your operations. Ultimate Versatility At Kessels, we understand that each industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-201 EC is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines isn't just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-201 EC Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Harness low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience uninterrupted power generation, regardless of variations in process steam demands, ensuring your operations run seamlessly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with the confidence that Kessels' expertise provides. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive landscape of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 EC Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-251EC Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unlock Unparalleled Efficiency with the Kessels MS-251 EC Extraction Condensing Steam Turbine: Where Precision Meets Power In the ever-evolving landscape of the oil and gas industry, precision, reliability, and sustainability reign supreme. Kessels Steam Turbines is proud to introduce the MS-251 EC Extraction Condensing Steam Turbine, a technological marvel that redefines excellence in steam turbine technology. Mastery of Extraction Condensing Turbines Extraction condensing turbines are the backbone of industries demanding a constant pressure steam flow for diverse processes. The MS-251 EC shares structural characteristics with condensing turbines, making it the ideal choice when you need a dependable source of constant pressure steam for your operations. Efficiency Perfected What sets the MS-251 EC apart is its remarkable capability to inject low-pressure steam from the second admission valve chest. This ingenious feature optimizes the utilization of available plant resources to meet power demands, making our turbine an indispensable asset in co-generation scenarios. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is paramount, the MS-251 EC excels. This turbine ensures your power generation remains steady, providing a rock-solid foundation for your operations. Ultimate Versatility At Kessels, we understand that each industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-251 EC is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines isn't just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-251 EC Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Harness low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience uninterrupted power generation, regardless of variations in process steam demands, ensuring your operations run seamlessly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with the confidence that Kessels' expertise provides. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive landscape of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-251 EC Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Unprecedented Power with the Kessels MS-102 Multistage Steam Turbine: The Apex of Efficiency and Reliability In the oil and gas industry, where power and precision are non-negotiable, Kessels Steam Turbines proudly presents the MS-102 Multistage Steam Turbine – a true marvel of engineering designed to redefine excellence in the world of steam turbines. Mastering Back-Pressure Turbines Back pressure turbines have long been the cornerstone of industrial steam applications, and our MS-102 Multistage Steam Turbine takes their capabilities to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines are the linchpin between boiler units and process steam headers, revolutionizing steam utilization and power generation. Efficiency Beyond Compare At the heart of the MS-102 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning perfectly with process demands. Every unit of electrical power generated is consumed precisely as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-102 turbine is not merely a machine; it's a versatile powerhouse ready to excel in an array of applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-102 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature is invaluable when low-volume steam demands and high tolerance for pressure variations are essential. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-102 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the most demanding environments. Unparalleled Versatility: Adapt effortlessly to changing needs, be it for drive applications or eco-friendly power generation, knowing that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-102 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

Elevate Your Operations with Kessels API-611 Compliant Steam Turbine: Where Precision Meets Excellence In the demanding realm of the oil and gas industry, precision, reliability, and adherence to standards are paramount. Kessels Steam Turbines takes pride in being a premier supplier of Steam Turbines that not only comply with but exceed the rigorous API-611 standards for general-purpose steam turbines. Setting New Standards in Steam Turbine Excellence Kessels Steam Turbines are at the forefront of driving pumps, fans, and compressors in Oil Refineries across the Middle East, India, and South East Asia. These turbines stand as testaments to our unwavering commitment to adhering to stringent design engineering practices set by oil giants and discerning end customers alike. Distinguishing Features of Kessels API-611 Single Stage Steam Turbines: Meets & Exceeds API-611 Standard: Our turbines not only meet but go beyond the API-611 standard, ensuring top-notch performance and reliability. Direct Drive Oil Relay Governors: Equipped with provisions for Direct Drive Oil relay constant speed governors conforming to NEMA class 'A' & NEMA class 'D'. Over Speed Mechanical Trip: Safety is paramount, and our turbines come with an over-speed mechanical trip with safety shut-off as standard. Versatile Gland Sealing: Gland sealing is achieved through carbon rings (up to six, removable), labyrinths, or mechanical steam seals. We offer the flexibility of choosing any combination of these three options. Impulse-Type Wheels: Provision for Single disc single-row, and Single disc two-row Curtis impulse-type wheels made of forged steel. Built-in Steam Strainer: As a standard feature, our turbines include a built-in steam strainer that is removable for your convenience. Versatile Support: Our turbines can be centerline or foot-mounted, offering flexibility in installation. Solenoid Trips: Provision for solenoid trips for remote shutdowns comes as standard, ensuring safety and control. Suitable for High Pressures: Built to handle high inlet and exhaust steam pressures, our turbines are robust and reliable. Horizontal and Vertical Orientation: Choose between horizontal and vertical shaft orientation to suit your specific needs. These features are a testament to our unwavering commitment to ensuring that customers can operate Kessels API-611 compliant Steam Turbines with complete peace of mind for their mechanical driving needs. Choose Kessels for Unparalleled Excellence Choosing Kessels Steam Turbines is a choice for excellence, precision, and reliability. Our API-611 Compliant Steam Turbines not only meet industry standards but surpass them, ensuring the highest levels of performance and safety for your operations. Empower Your Operations with Kessels In the competitive landscape of the oil and gas industry, precision and reliability are non-negotiable. Elevate your operations with the Kessels API-611 Compliant Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Envío:

Situado en:

India

![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

Tubing hangers form part of the primary well barrier while holding the tubing string in place. The tubing hanger is screwed to the top joint of tubing (or pup-joints as required for space out), and is landed in the casing flange (in compression or tension depending on the wellhead assembly) with the elastomeric seals preventing communication between the tubing and A-annulus. Our tubing hangers come in a variety of sizes and specifications for various wellhead manufacturers including Cameron, FMC, Stream-Flo, ABB, Vetco-Gray, and Barbour systems to name a few. We stock inventory from vintage systems, as well as modifying hangers for additional feed-throughs for control lines, electric feed-thru, or downhole fiber-optic as required.

Buy

In Stock

New

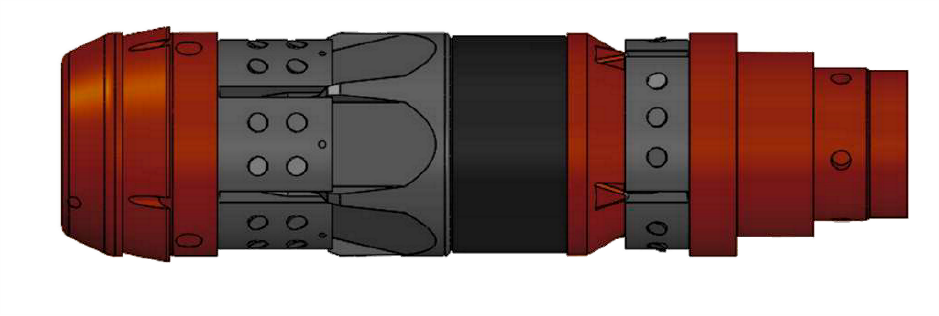

WI Subsurface Safety Valve 2.72 inch

WI Valve![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

The WI retrievable injection valve is a high-performance, high-flow rate injection valve. High throughput is achieved by a unique valve configuration that minimizes turbulent and potentially erosive flow. Operation is not dependent on a specific flow rate, pressure, or setting depth, thus negating the need for adjustment over time. The valve incorporates a metal-to-metal valve and seat energized by the combination of an integral spring and well pressure acting from below. The WI injection valve can be deployed on a wireline lock or through-tubing pack-off device, providing flexibility not available with alternative injection valve systems. As a result of the simple design with fewer parts, redress and repair costs are considerably lower than those for other injection valve systems. Applications The WI injection valve is primarily used in water injection applications as an alternative to conventional tubing or wireline-set safety valves. The valve is also commonly used as a retrofit solution in water injectors in which a tubing to annulus leak has occurred. The valve can be deployed below the leak point to eliminate uncontrolled annulus pressure increases when the injection stops. Features » Compatible with all known lock systems » Dedicated designs to suit Halliburton EB0 intervention packers » Enhanced internal flow profile » Simple design and construction » Flow-loop testing performed to establish pressure drop versus pump rate *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Sea Freight

Bigbore 9-5/8 inch Surface Controlled Subsurface Safety Valve Wireline Retrievable

WR-SCSSSV Bigbore 9-5/8![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

The manufacturer has applied the same stringent testing used on its maximum reliability tubing-retrievable safety valves (TRSV) to its BigBore™ wireline-retrievable safety valve (WLRSV). This valve offers the durability and reliability of TRSVs through metal-to-metal (MTM) sealing of the contoured flapper, enhanced body connections, and debris isolation. The contoured flapper provides a large ID compared to other valve designs, while providing enhanced flapper sealing. Another significant feature of this valve is its ease of on-location servicing. The construction of the upper end of the valve provides for easy access to the valve’s external packing. Once the lock is removed, the packing retainer sleeve can be removed and serviced. The savings made possible by an enlarged ID, enhanced performance, and ease of service have made it an excellent choice for replacing equipment currently installed in existing completions. Applications » New completions » Replacement of existing WLRSVs to provide increased ID and reliability Features » MTM sealing contoured flapper closure with large ID » High-strength rod-piston actuation » Dual-sealing minimized body connections » Enhanced debris isolation through MTM interface of flow tube/bottom sub » Radius of curvature at flow entrance » Equalizing feature available » Designed for easy field servicing » Setting depths to 9,000 ft (2743 m) *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

Welding Machine TIG AC/DC 501 Pulse

Welder![]() Canaweld Inc. en Vaughan

Canaweld Inc. en Vaughan

Unleash Precision Welding with the TIG AC/DC 501 Pulse! At Canaweld, we take pride in providing the oil and gas industry with welding solutions that redefine excellence. Introducing the TIG AC/DC 501 Pulse – a welding powerhouse that embodies power, intelligence, and versatility. Crafted to meet the demands of professional production TIG welders, this welding machine sets the standard for precision and performance. Unmatched Versatility The TIG AC/DC 501 Pulse empowers you with the freedom to choose between AC or DC TIG welding, including stainless steel, mild steel, or aluminum, as well as Stick welding. Whatever your welding application demands, this welding marvel delivers impeccable results, leaving no room for compromise. Power Meets Intelligence Equipped with advanced TIG welding parameters, the TIG AC/DC 501 Pulse allows you to fine-tune your welding process, ensuring exceptional welds tailored to your specific applications. The easy-to-use interface with digital adjustment of all welding parameters puts you in complete control, simplifying your welding experience. Unparalleled Monitoring and Control Experience full monitoring of welding parameters with the digital ammeter and voltmeter, offering precise current presetting and a convenient hold function. The welding process selector enables seamless switching between TIG AC, TIG DC, TIG DC 'Lift,' and MMA modes, catering to diverse welding needs. Choose from 2 Stroke, 4 Stroke, Cycle, and Spot Timer modes with the welding mode selector, adding flexibility to your welding operations. Personalized Welding Programs The TIG AC/DC 501 Pulse takes customization to new heights, allowing you to store personalized welding programs, memorizing your preferred settings for each unique project. This feature streamlines your workflow and ensures consistency in every weld. Precision Pulse TIG Welding Achieve precision like never before with pulse TIG welding, adjustable from 0.5 up to 200 Hz, and take advantage of the "EASY PULSE" feature for added convenience. Fine-tune your welding experience with AC square wave balance and Balance Plus adjustments, as well as AC square wave frequency control. Unleash Your Creativity With the TIG AC/DC 501 Pulse, you have the power to control the arc striking and arc dynamics with tungsten rod diameter presetting. Explore the wave selector with Square, Mixed, Sinusoidal, and Triangular options, providing you with endless possibilities for your welding projects. The Canaweld Promise As with all Canaweld products, the TIG AC/DC 501 Pulse embodies durability, reliability, and excellence. Our commitment to quality and customer satisfaction is reflected in our comprehensive 3-year warranty, giving you the peace of mind you deserve. Elevate your welding capabilities with the TIG AC/DC 501 Pulse. Unleash precision welding like never before and let Canaweld be your trusted partner in achieving welding perfection. Embrace power, intelligence, and versatility with the TIG AC/DC 501 Pulse - Welding Perfected!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

The T, T-CL, C-SRL-CL and CXS Tubing Hangers are all single completion, mandrel-type hangers for use in either the C Tubing Spool or the CD-2 Tubing Spool. T Tubing Hanger The T Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. Its flexible neck maintains the metal seal despite thermal or pressure cycling. T-CL Tubing Hanger The T-CL Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. A control line exit block is available in either a bull plug style or block needle valve style. C-SRL-CL Tubing Hanger The C-SRL-CL Tubing Hanger incorporates a pressure energized SRL neck seal which accommodates vertical movement in the tubing hanger during BOP testing. A control line exit block is available in either a bull plug style or block needle valve style. The C-SRL-CL hanger should be used in 7-1/16” 10,000 psi Type C Tubing Spools. CXS Tubing Hanger The CXS Tubing Hanger includes two neck seals which may be used to isolate one control line.

Buy

In Stock

Product

Used

API

Air Freight

EnviroBlu 4 Litre Industrial Cleaner

EnviroBlu Cleaner and Degreaser![]() Mekapisk EnviroBlu Solutions Inc. en St. John’s

Mekapisk EnviroBlu Solutions Inc. en St. John’s

Industrial Cleaning with the 4-Litre EnviroBlu: The Future of Efficiency and Sustainability At Mekapisk EnviroBlu Solutions Inc., we believe in pushing the boundaries of what’s possible in industrial cleaning. Imagine a cleaner that’s tough enough to handle the biggest jobs yet compact enough to manage with ease. Introducing our 4-litre EnviroBlu cleaner—a marvel of engineering designed to transform your cleaning routine. This isn’t just a cleaner; it’s a revolution in how we approach maintenance and sustainability. The Power of EnviroBlu Efficiency and Speed In an industry where time is money, every second counts. EnviroBlu’s advanced aqueous surfactant technology penetrates dirt and grime at the molecular level, ensuring a quick and thorough clean. Whether you’re dealing with industrial machinery, large equipment, or expansive surfaces, EnviroBlu makes the job faster and easier. Imagine cutting your cleaning time in half—that’s the power of EnviroBlu. Cost Savings Efficiency isn’t just about speed; it’s also about reducing costs. EnviroBlu’s potent formula means you use less product to achieve superior results. This translates to significant cost savings over time. Our 4-litre size is perfect for big cleaning jobs, providing enough product to tackle extensive tasks without the need for frequent resupply. Lower product usage, less downtime, and fewer purchases—all adding up to a healthier bottom line. Environmental Stewardship We’re living in a time when environmental responsibility is not just an option but a necessity. EnviroBlu’s water-based, non-toxic, phosphate-free formula is designed to be safe for both people and the planet. This isn’t just about cleaning; it’s about preserving our environment for future generations. By choosing EnviroBlu, you’re making a powerful statement about your commitment to sustainability. Why the 4-Litre Size is a Game Changer Big Jobs, Easy Handling The 4-litre EnviroBlu bottle is designed to strike the perfect balance between capacity and manageability. It’s large enough to handle extensive cleaning tasks but compact enough to be easily handled and stored. This means you get the power of an industrial-strength cleaner in a size that’s practical for everyday use. Versatility From heavy-duty industrial equipment to everyday residential cleaning, EnviroBlu’s versatility makes it an indispensable tool. Its powerful cleaning action is perfect for a wide range of applications, including: • Industrial machinery and equipment • Vehicles and heavy-duty trucks • Large commercial spaces • Residential areas, including kitchens and bathrooms Certified Safe EnviroBlu is certified food safe by the Canada Food Inspection Agency (CFIA) and is a recognized Green Marine Partner. This ensures that our product is safe to use in diverse environments, including food processing areas and maritime industries. You can clean with confidence, knowing you’re meeting the highest safety standards. Directions for Use Smaller, Less Soiled Areas: 1. Mix water with EnviroBlu as per the required dilution ratio. 2. Spray the mixed solution directly on the surface. 3. Wipe the area with a dry cloth. Larger, Heavily Soiled Areas (Without Power Washer): 1. Pre-rinse the affected area with water. 2. Spray EnviroBlu directly on the target area and let it work for 1-3 minutes. 3. Brush the area if necessary. 4. Rinse thoroughly with water. 5. Repeat if the area has not been cleaned recently. Larger, Heavily Soiled Areas (With Power Washer): 1. Spray the area with a water jet only. 2. Introduce EnviroBlu into the power washer. 3. Rinse with straight water. Stay Green, Go Blu! Choose the 4-litre EnviroBlu for your big cleaning jobs. Experience the unmatched efficiency, cost savings, and environmental stewardship that only EnviroBlu can provide. Let’s transform the way we clean and build a more sustainable future together.

Buy

In Stock

Manufacturer

New

ISO

Land Freight

Mud pump for circulating and drilling in extreme conditions

Mud Circulation System![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie

The Bomco Triplex Mud Pump has a herringbone design and is interchangeable with the Continental Emsco FB model. Mud pumps serve as the heart of the mud circulating system. Reciprocating piston pumps (also called slush pumps or power pumps) are widely used for drilling oil and gas wells. The advantages of the reciprocating positive-displacement pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameters of the compression cylinders (pump liners) and pistons. A pump that has single-action strokes in three cylinders is called a triplex pump.

Buy

In Stock

Distributor

New

API

Sea Freight

Timesheets and Resource loading Platform

KEY360![]() KEY360 Inc en New York, NY

KEY360 Inc en New York, NY

KEY360 Inc offers a single integrated Business Management Platform comprising Business Intelligence, Project Management, Big Data & Analytics, ERP, Behaviour and Strategy Modification. - Over 140 Business and Project Management Systems on one platform available - Unique and extremely effective workflow engine - Remarkable “BIG DATA” and bulk transaction capability - Integrated Real Time reporting and dashboarding - Multi-company platform allows all project users to integrate seamlessly KEY Differentiators: - KEY360 Provides an exceptional opportunity for your organisation to attract new clients and build long terms relationships. - KEY360 is a Microsoft Gold Partner and Approved Microsoft Co-Sell Partner and can be purchased directly from the below online marketplaces: - Microsoft AppSource: KEY360 Capital Management Projects - Azure Marketplace: KEY360 Capital Management Projects - KEY360 is reputedly the most comprehensive and versatile Capital Project Management, Business Digitalization & Business Optimization solution available.

Service

In Stock

Service

New

ISO

![]() Hoca Oil Tools en Zwartemeer

Hoca Oil Tools en Zwartemeer

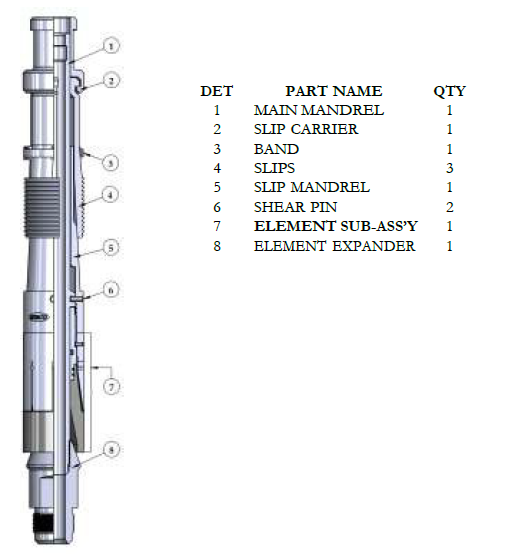

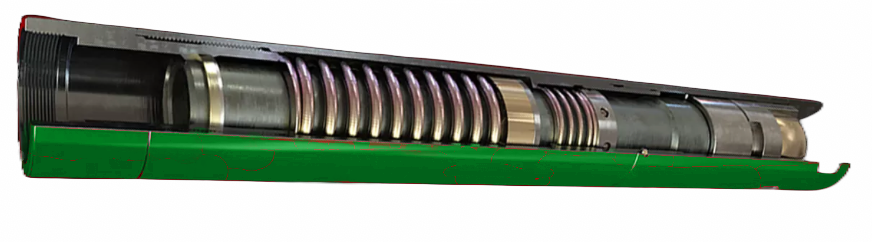

Unlocking Efficiency: HOCA Oil Tools' Lock Mandrels for Tubing In the demanding realm of oil and gas operations, ensuring the integrity and functionality of well components is paramount. HOCA Oil Tools, a pioneer in downhole slick line tools, introduces its cutting-edge Lock Mandrels for Tubing – an essential solution designed to enhance the performance and reliability of downhole activities. These tools are engineered for precision, delivering unmatched reliability and performance to meet the rigorous demands of modern well operations. HOCA's Lock Mandrels for Tubing: Precision-Engineered for Superior Performance Our Lock Mandrels for Tubing are designed to securely latch into the tubing string, providing a stable base for various downhole tools and devices. Tailored to accommodate different tubing sizes and pressures, they are essential for the effective management and control of wellbore fluids. Fabricated from high-quality materials and built to withstand the harshest downhole environments, HOCA's Lock Mandrels ensure operational success and longevity. Experience the HOCA Oil Tools Advantage Opting for HOCA Oil Tools’ Lock Mandrels for Tubing means choosing a partner committed to your operational success. Our dedication to quality and innovation ensures that our products not only meet but exceed the expectations set by the demanding oil and gas industry. Incorporating our Lock Mandrels into your tubing operations signifies a step towards enhanced efficiency, safety, and control. With HOCA Oil Tools, you gain more than just equipment; you gain a strategic advantage supported by our expertise and unwavering commitment to excellence. Choose HOCA Oil Tools for your downhole needs and join the ranks of satisfied clients who rely on our Lock Mandrels for Tubing to secure their operational success. Partner with us, and harness the power of precision-engineered solutions to elevate your downhole activities. With HOCA Oil Tools, empower your downhole operations with tools that redefine reliability, efficiency, and performance in the oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

Plug with Equalizing Prong and Valve Sub-Assembly

Downhole Tools![]() Hoca Oil Tools en Zwartemeer

Hoca Oil Tools en Zwartemeer